235ml anchoring system polyester chemical anchor

GU-100 235ml

Two component chemical rebar grouting

Small volume 235ml side by side polyester chemical anchor is easy use for small area and most popular size in Taiwan domestic market. It needs a specific caulking gun to extrude the mortar.

Polyester with styrene chemical anchor is classic and most popular material for general purpose. Economical price satisfies most fixing demands of medium loads. Applicable for rebar doweling, handrail, facade, pipelines, awnings, brackets. All of our chemical mortar had tested and approved in Germany and France. There are 150ml, 345ml, 360ml and 380ml available in the range.

Chemical fixing system - Economical polyester with styrene

Easy setting injectable mortar for anchoring in concrete and for rebar connections. Based on market oriented we offer various volumes and different mixing ratio. Polyester chemical anchor is designed with 10:1 mixing ratio. 150ml chemical anchor is packed in coaxial cartridge. It can be used with standard silicone gun, no extra dispensing tool required and perfect solution for one time consumption. 235ml chemical anchor is the best selling capacity for Taiwan market. 345ml and 360ml chemical anchor are popular export items which are more flexible for applications. 380ml coaxial chemical anchor is economic volume for large construction projects. Polyester injectable adhesive is the best choice for beginner to achieve mostly basic fixing demands.

Specification of Polyester chemical anchor

● Material: Polyester with styrene

● Model Number: GU-100

● Capacity: 235ml

● Mixing Ratio: 10:1

● Mixed Color: Gray

● Shelf Life: 12 months

● Standard Package: One cartridge with one mixer

● Other Accessory: Mixer, caulking gun, nylon sleeve, air pump, brush

Polyester chemical anchor is good option for general anchoring purpose

● Loading strength approved by Germany lab

● No expansion effect and allowing fixing close to the edges

● Low level of volatile organic compounds (VOC) according to LEED test

● Cost-efficient and long durability

● Suitable for vertical or horizontal fixings

● Medium loads for general anchoring purpose

● Private label or customized design by demands

Polyester chemical anchor adhesive for home repairing

Low VOC and small volume for house fixing and repair. Convenience installation and easy replace expansion anchor with higher bonding strength. Compare to traditional way of fastener fixing, chemical fixings offer better heavy loading performance. For general application of fixture, polyester is acceptable price and satisfied performance for most demands. It's common, mature item and widely apply to construction.

How to install chemical anchor?

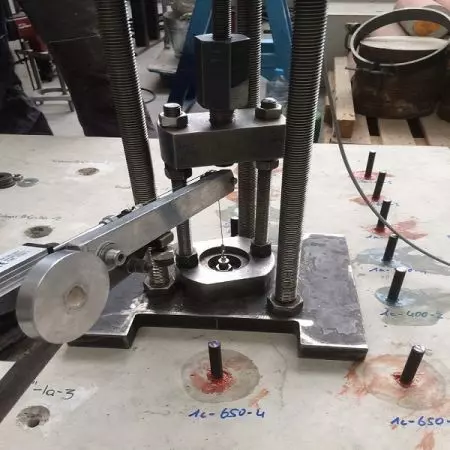

1. Drill the specific diameter and depth. 2. Clean dust with brush and air blow pump. 3. Press out unmixed mortar which cannot be used. 4. Inject mixed mortar from the bottom of the drilled hole. 5. Insert and rotate the rebar/threaded rod/steel strip into the drilled hole. Don't touch the insert until full curing. Curing time refer to our TDS. The installation process will affect the bonding performance of chemical anchors.

All Good Use chemical anchors qualified by IWB lab in Germany and CSTB lab in France

There is no authorized lab for testing bonding anchor in Asia under European Technical Assessment (ETA) regulations. All our chemical anchors are tested according to EAD 330087-01-6001 and EAD 330499-00-0601 for fastener of rebar and threaded rods. We cooperate and consult with leading experts in Europe who dedicate in the fasteners field for more than two decades. We keep improving our research capacity and upgrade international approvals of chemical anchor.

Technical Data

CHART 1. SOLID SUBSTRATE REBAR INSTALLATION DETAILS

| Pressure | Destroy Haul Strength (Kgf/KN) | Safety Haul Strength (Kgf/KN) | Working Standard (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Concrete Strength | 4,000 psi | 280 kg/cm2 | 4,000 psi | 280 kg/cm2 | Hole Diameter | Hole Depth | |||

|

Rebar |

#3 | (Φ10) | 3,070 | 31.0 | 1,023 | 10.0 | 13 | 90 | |

| #4 | (Φ12) | 4,920 | 49.7 | 1,640 | 16.6 | 16 | 120 | ||

| #5 | (Φ16) | 6,800 | 68.7 | 2,267 | 22.9 | 20 | 145 | ||

| #6 | (Φ20) | 7,708 | 77.9 | 2,569 | 25.9 | 25 | 170 | ||

| #7 | (Φ22) | 9,440 | 95.4 | 3,147 | 31.8 | 28 | 200 | ||

| #8 | (Φ25) | 13,620 | 137.6 | 4,540 | 45.9 | 32 | 225 | ||

| #9 | (Φ29) | 20,340 | 205.6 | 6,780 | 68.5 | 37 | 250 | ||

| #10 | (Φ30) | 26,620 | 269.0 | 8,873 | 89.6 | 40 | 290 | ||

| Remarks: | 1. Concrete Strength fc': 280kg/cm2 (4,000 psi) 2. Rebar Strength: #3~#5 fy: 2,800 kgf/cm2, #6~#11 fy= 4,200 kgf/cm2 |

||||||||

CHART 2. CURING TIME TABLE

| Temperature (°C) | Gelling | Full Curing |

| 0~5 | 8 hr. | |

| 5~10 | 40 min. | 7 hr. |

| 10~20 | 30 min. | 6 hr. |

| 20~30 | 8 min. | 3 hr. |

| 30~40 | 3 min. | 2 hr. |

| Please make pull off test for at least 24 hours after full cured. | ||

CHART 3. FIXING CONSUMPTION PER CARTRIDGE

| Anchor Size | Hole Diameter (mm) |

Hole Depth (mm) |

Number of Fixings | ||||

| 150ml | 235ml | 345ml | 360ml | 380ml | |||

| M8 | 10 | 80 | 30 | 47 | 69 | 72 | 76 |

| M10 | 12 | 90 | 18 | 29 | 42 | 44 | 47 |

| M12 | 14 | 110 | 11 | 17 | 25 | 27 | 28 |

| M16 | 18 | 125 | 6 | 9 | 14 | 14 | 15 |

| M20 | 24 | 170 | 2 | 4 | 6 | 6 | 6 |

| M24 | 28 | 210 | 1 | 2 | 3 | 4 | 4 |

| M30 | 35 | 270 | 1 | 1 | 2 | 2 | 2 |

| M36 | 40 | 330 | X | 1 | 1 | 1 | 1 |

| Note: Based on continuous installation without interruptions or nozzle changes. Provided as a guide and will vary with temperature. | |||||||

- Related Products

-

235ml anchor system epoxy acrylate chemical anchor

GU-600 235ml

235ml epoxy acrylate chemical anchor is small volume and good for home DIY with quick setting...

Details235ml injectable vinylester chemical anchor

GU-2000 235ml

235ml vinylester injection chemical anchor mortar is a high performance and rapid curing two-part...

Details150ml anchoring system polyester chemical anchor

GU-100 150ml

150ml polyester chemical anchor is the smallest volume in the range. It is available to work...

Details345ml anchoring system polyester chemical anchor

GU-100 345ml

345ml polyester chemical anchor is middle size and more flexible in market. It needs a specific...

Details360ml anchoring system polyester chemical anchor

GU-100 360ml

360ml polyester chemical anchor is middle size and more flexible in market. It needs a specific...

Details380ml anchoring system polyester chemical anchor

GU-100 380ml

380ml polyester co-axial cartridge chemical anchor also called 400ml or 410ml cartridge in the market....

Details360ml two component caulking gun

#811N

#811N is multi compatible dispenser for 300/345/360ml adhesive cartridge and some customers...

DetailsMixing nozzle for 10:1 chemical anchor

#817

Mixing nozzle is designed to mix and dispense two-component chemical anchor at the same time....

Details - Files Download

-

Polyester Resin with Styrene Catalogue

Bonding strength chart on dry concrete by different hole size and depth. Economic polyester for all fixing demands.

DownloadGU-100 Polyester Resin with Styrene Technical Data Sheet

Technical information of anchor design, curing time, edge distance, consumption per hole and installation procedure.

DownloadGU-100 SGS Tensile Strength Testing Report

Polyester pull out strength report for diverse bolt size on 4000psi concrete according to ASTM E488-96 by SGS lab.

DownloadGU-100 AIT Tensile Strength Diameter of 25mm

Polyester tensile test report of rebar fixing for 25mm hole size by Thailand AIT engineering lab. According to local market demands, our products will...

DownloadGU-100 AIT Tensile Strength Diameter of 16mm

Polyester tensile test report of rebar fixing for 16mm hole size by Thailand AIT engineering lab. According to local market demands, our products will...

Download - Installation Guide

- Gallery

235ml anchoring system polyester chemical anchor - Two component chemical rebar grouting | Sold in 40 Countries Injectable Chemical Anchors Manufacturer Since 1997 | Good Use

Located in Taiwan since 1997, Good Use Hardware Co., Ltd. has been an injectable adhesive mortars and anchors manufacturer. Their main products, including 235ml anchoring system polyester chemical anchor, injection cartridges, chemical mortars, chemical anchors, anchor capsules, polyester resins and vinylester resins, which are sold in 40 countries.

Reputable factory of chemical anchor in Taiwan produces the widest range of adhesive anchor solutions for your concrete anchoring applications. with more than 15 years manufacturing experience for Chemical Anchor System, Injection Cartridge System, Construction Chemical Mortar and more. Certified chemical anchor solutions with wide selections of adhesive materials including epoxy anchors, concrete anchors, resin anchors for heavy loads in rebar application, diamond drilled holes and anchoring in solid concrete. Non-drip formula, ideal for overhead installation. Chemical anchor bolt and anchor fixings included for efficient, hassle-free, labor-saving chemical anchoring.

Good Use has been offering customers certified and tested high-quality chemical anchors, both with advanced technology and 25 years of experience, Good Use ensures each customer's demands are met.