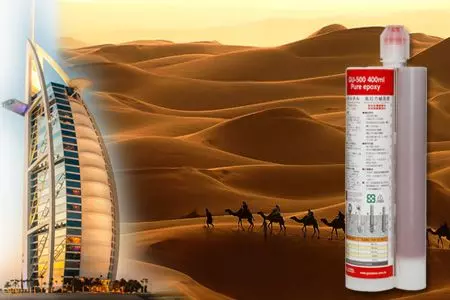

Anclaje químico de epóxido inyectado aprobado por ETA, diseñado para la retrofitting de barras de anclaje

GU-500SD 400ml 3:1

Mortero de anclaje químico de epóxido inyectado diseñado para su uso en concreto húmedo

El anclaje químico de epoxi puro GU-500SD ha recibido con éxito el informe de Evaluación Técnica Europea ETA-24/0928, confirmando su alto rendimiento y fiabilidad para aplicaciones estructurales. La evaluación se llevó a cabo de acuerdo con EAD 330087-01-0601, abarcando una amplia gama de condiciones, incluyendo entornos de alta alcalinidad, atmósferas sulfurosas, resistencia a la corrosión y rendimiento ante la exposición al fuego.

Este anclaje químico de epóxido puro de alto rendimiento está diseñado específicamente para conexiones de varilla de refuerzo y anclajes de alta resistencia en concreto seco, húmedo y sin fisuras. Su formulación avanzada ofrece una excepcional resistencia de unión y durabilidad a largo plazo en un amplio rango de temperaturas, lo que la convierte en una opción confiable incluso para las aplicaciones estructurales más exigentes. Certificado y probado en calidad por laboratorios acreditados en Alemania y Francia, el anclaje químico epóxico GU-500SD presenta una consistencia que no se deforma, lo que permite una instalación limpia y efectiva en aplicaciones suspendidas en overhead o verticalmente, como techos y alfeizares. Para mayor flexibilidad en el lugar de trabajo, el GU-500SD también está disponible en un cartucho de 585 ml, ideal para tareas de anclaje a gran escala o continuas.

Sistema de Fijación Química - Anclaje de Epoxi Puro de Rendimiento Definitivo

Un mortero epóxico de alto rendimiento diseñado para anclajes de alta resistencia. Este anclaje químico avanzado es ideal para aplicaciones que requieren un rendimiento superior para garantizar un anclaje seguro en condiciones críticas, variaciones de temperatura o limitaciones de instalación. Probado en diversos escenarios de anclaje en un laboratorio aprobado por ETAG, proporcionamos informes de comparación para demostrar sus capacidades. Nuestro anclaje adhesivo inyectable epóxico es uno de los sujetadores de unión más fuertes disponibles, satisfaciendo la creciente demanda de soluciones de anclaje confiables.

Especificación del Anclaje Químico de Epoxi Puro Definitivo

● Material: Epoxi puro

● Número de modelo: GU-500SD

● Capacidad: 400ml

● Relación de mezcla: 3:1

● Color de mezcla: Naranja

● Vida útil: 18 meses

● Paquete estándar: Un cartucho con un mezclador

● Otro accesorio: Mezclador, pistola de calafateo, funda de nylon, bomba de aire, brocha

El anclaje químico de epoxi puro es adecuado para trabajar en un amplio rango de temperaturas

● Funciona en temperaturas bajas y altas

● Disponible para instalación en agujeros de concreto húmedo (Reducción de las cargas recomendadas del 20%)

● Carga de trabajo pesada

● No se deforma para aplicaciones en techos y paredes

● Buen rendimiento en fijaciones críticas

● Ideal para incrustaciones profundas y agujeros grandes

● Sin contracción

● Libre de estireno, bajo olor y probado por LEED para VOC (Compuestos Orgánicos Volátiles)

● Sin preocupaciones de salud o seguridad que ralenticen su trabajo

● Certificado ETA-24/0928

● Lograr una vida útil de 50 años

Epóxido químico no sag para anclaje en clima frío

Nuestro mortero epóxico puro de alta resistencia ofrece un rendimiento excepcional para conexiones de varilla y anclajes pesados, incluso en condiciones de frío. Adecuado para su uso durante todo el año en todas las estaciones, también es fácil de almacenar. Para entornos extremadamente fríos, recomendamos considerar material de viniléster, o puede contactarnos para una fórmula personalizada adaptada a sus necesidades específicas. Esto garantiza un rendimiento de anclaje confiable, sin importar la temperatura.

Mortero de inyección epóxica para anclaje en concreto húmedo

Nuestra epóxica de alta calidad está diseñada para cumplir con todos los requisitos de fijación y anclaje, ofreciendo un rendimiento confiable incluso en condiciones desafiantes. La epóxica GU-500SD se puede instalar con éxito en concreto húmedo, proporcionando excelentes resultados de anclaje. Sin embargo, tenga en cuenta que la resistencia de unión puede ser menor en comparación con la instalación en concreto seco. Tenemos informes de rendimiento de laboratorios líderes disponibles para su referencia. No dude en contactarnos para más detalles.

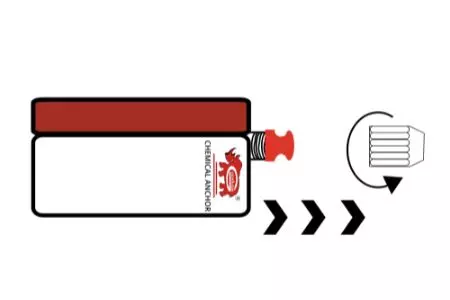

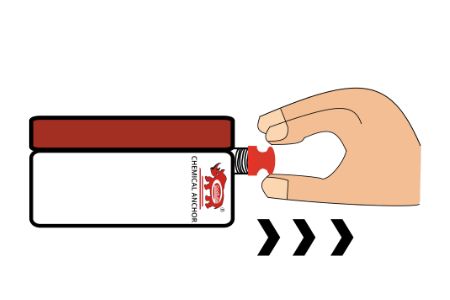

¿Cómo usar una pistola de calafateo con anclaje químico?

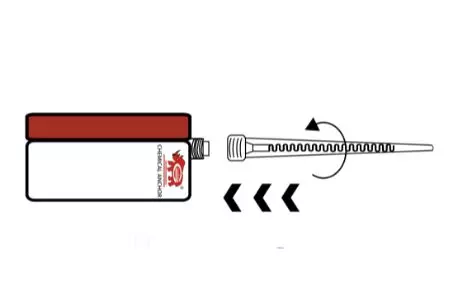

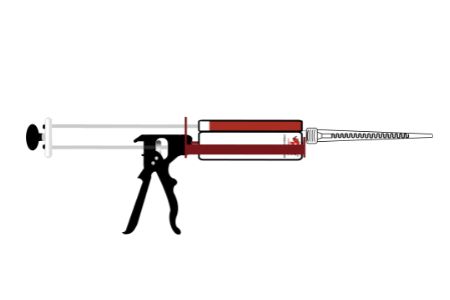

1. Liberar la Varilla de Acero: Localice el pequeño disparador en la parte posterior de la pistola de calafateo. Presiona el disparador de liberación con tu pulgar para aflojar la larga varilla de acero que atraviesa el marco. 2. Tire del émbolo hacia atrás: Tire completamente del émbolo para preparar el arma para su uso. 3. Preparar el tubo: Retire la tapa blanca y el tapón del tubo. A continuación, atornille la boquilla del mezclador al tubo. Inserte el extremo plano del tubo en la parte trasera de la pistola de calafateo, con el tubo y la boquilla mezcladora posicionados en la parte delantera. 4. Cargar el tubo: Tira del gatillo del mango para mover los émbolos de la pistola de calafateo. Asegúrese de que los émbolos estén correctamente alineados con los pistones del tubo. La correcta colocación del tubo es crucial para una aplicación adecuada. Siguiendo estos pasos, puede garantizar un uso suave y efectivo de la pistola de calafateo de anclaje químico.

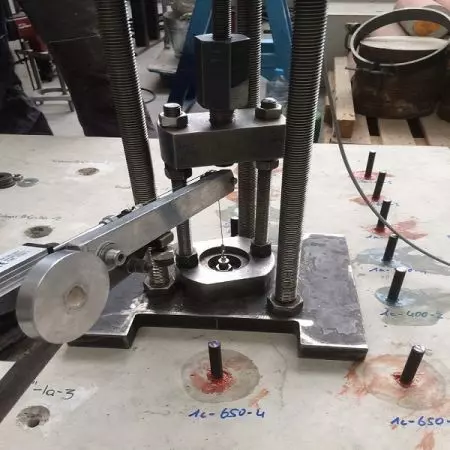

Good Use Anclajes Químicos - Calificados por el Laboratorio IWB en Alemania y el Laboratorio CSTB en Francia

Actualmente, no hay laboratorios acreditados en Asia equipados para probar anclajes de unión de acuerdo con los estándares de Evaluación Técnica Europea (ETA). Para garantizar la más alta calidad y cumplimiento, nuestros anclajes químicos son rigurosamente probados de acuerdo con EAD 330087-01-0601 y EAD 330499-00-0601, cubriendo aplicaciones tanto para fijaciones de varilla de refuerzo como de varilla roscada. Nuestro producto insignia, el anclaje químico epóxico GU-500SD, ha sido oficialmente aprobado por ETA según la norma EAD 330087-01-0601, verificando su rendimiento bajo estrictos requisitos europeos. Colaboramos estrechamente con expertos europeos líderes que aportan más de 20 años de experiencia en la industria de fijación y anclaje. Esta asociación, combinada con nuestro fuerte enfoque en la investigación y el desarrollo, garantiza una innovación continua de productos y la expansión continua de nuestras certificaciones internacionales para soluciones de anclaje químico.

Datos Técnicos

DETALLES DE INSTALACIÓN DE REFORZAMIENTO EN SUSTRATO SÓLIDO

| Presión | Resistencia a la Tracción de Ruptura (Kgf/KN) | Resistencia a la Tracción de Seguridad (Kgf/KN) | Estándar de Trabajo (mm) | ||||||

| Resistencia del Concreto | 4,000 psi | 280 kg/cm2 | 4,000 psi | 280 kg/cm2 | Diámetro del Agujero | Profundidad del Agujero | |||

| Barra de refuerzo No. | #3 | (Φ10) | 3.622 | 36.6 | 1.207 | 12.2 | 13 | 90 | |

| #4 | (Φ12) | 6,437 | 65.0 | 2,146 | 21.7 | 16 | 125 | ||

| #5 | (Φ16) | 9,737 | 98.4 | 3,246 | 32.8 | 20 | 145 | ||

| #6 | (Φ20) | 13,715 | 138.5 | 4,572 | 46.2 | 25 | 170 | ||

| #7 | (Φ22) | 18,754 | 189.4 | 6,215 | 63.1 | 28 | 200 | ||

| #8 | (Φ25) | 24,137 | 243.8 | 8,046 | 81.3 | 32 | 225 | ||

| #9 | (Φ28) | 27,484 | 277.6 | 9,161 | 92.5 | 37 | 260 | ||

| #10 | (Φ32) | 31,869 | 321.9 | 10,623 | 107.3 | 40 | 290 | ||

| #11 | (Φ36) | 36,000 | 363.6 | 12,000 | 121.2 | 42 | 320 | ||

| Observaciones: | 1.Resistencia del concreto fc': 280kg/cm2 (4,000 psi) 2.Resistencia de la barra de refuerzo: #3~#5 fy: 2,800 kgf/cm2, #6~#11 fy= 4,200 kgf/cm2 |

||||||||

TABLA DE TIEMPO DE CURADO

| Temperatura (°C) | Gelificación | Curado Completo |

| 5~9 | 2 hr. | 90 hr. |

| 10~14 | 90 min. | 64 hr. |

| 15~19 | 45 min. | 28 hr. |

| 20~29 | 30 min. | 18 hr. |

| 30~39 | 20 min. | 7 hr. |

| 40 | 12 min. | 5 hr. |

| Por favor, realice la prueba de despegue durante al menos 24 horas después de curar completamente. | ||

CONSUMO FIJO POR CARTUCHO

| Tamaño del ancla |

Diámetro del Agujero (mm) |

Profundidad del Agujero (mm) |

Número de fijaciones |

| 400ml | |||

| M8 | 10 | 80 | 80 |

| M10 | 13 | 90 | 42 |

| M12 | 16 | 120 | 21 |

| M16 | 20 | 145 | 11 |

| M20 | 25 | 170 | 6 |

| M24 | 28 | 210 | 4 |

| M30 | 35 | 270 | 2 |

| M36 | 40 | 330 | 1 |

| Nota: Basado en la instalación continua sin interrupciones ni cambios de boquilla. Proporcionado como guía y variará con la temperatura. | |||

- Productos RelacionadosDescarga de archivosGuía de InstalaciónGalería

Anclaje químico epóxico de 400ml diseñado para su uso en condiciones climáticas tropicales

GU-500 400ml 3:1

Este anclaje químico de epoxi de 400 ml, en un cartucho injectable 3:1, está diseñado para...

DetallesAdhesivo epóxico de anclaje de 650ml para instalaciones a alta temperatura

GU-500 650ml 1:1

Este mortero de inyección a base de epoxi de 650 ml, con una relación de 1:1 y curado lento,...

DetallesAnclaje químico de epoxi de alta resistencia aprobado por ETA para sistemas de montaje en concreto

GU-500SD 585ml 3:1

GU-500SD es nuestra solución de anclaje de epoxi puro de alto rendimiento aprobada por ETA,...

DetallesPistola de calafateo de resina epoxi de dos componentes estándar de 400ml

#810

La pistola de calafateo #810 es una opción de precio para cartuchos de epoxi de dos componentes...

DetallesPistola aplicadora de epoxi de cartucho premium de 400ml lado a lado

G34-400LA

El dispensador G34-400LA es resistente y eficiente para dispensar adhesivo epoxi de 3:1 de 400 ml. Mango...

DetallesBoquilla de mezcla para anclaje químico 1:1 y 3:1

#818

Las boquillas mezcladoras estáticas se aplican a los cartuchos de adhesivo para mezclar y dispensar...

Detalles

Catálogo electrónico de Good Use

Encuentre nuestro catálogo completo de gama de anclajes químicos

Anclaje químico de epóxido inyectado aprobado por ETA, diseñado para la retrofitting de barras de anclaje - Mortero de anclaje químico de epóxido inyectado diseñado para su uso en concreto húmedo | Fabricante de anclajes químicos inyectables vendidos en 40 países desde 1997 | Good Use

Ubicada en Taiwán desde 1997, Good Use Hardware Co., Ltd. ha sido un fabricante de morteros y anclajes adhesivos inyectables. Sus productos principales, que incluyen anclajes químicos epóxicos inyectables aprobados por ETA diseñados para la retrofitting de barras de anclaje, cartuchos de inyección, morteros químicos, anclajes químicos, cápsulas de anclaje, resinas de poliéster y resinas de viniléster, se venden en 40 países.

Fábrica de anclajes químicos de renombre en Taiwán produce la gama más amplia de soluciones de anclaje adhesivo para sus aplicaciones de anclaje en concreto. con más de 15 años de experiencia en la fabricación de sistemas de anclaje químico, sistemas de cartuchos de inyección, mortero químico para la construcción y más. Soluciones certificadas de anclaje químico con amplia selección de materiales adhesivos, incluyendo anclajes de epoxi, anclajes de concreto, anclajes de resina para cargas pesadas en aplicaciones de barras de refuerzo, perforaciones con brocas de diamante y anclaje en concreto sólido. Fórmula antigoteo, ideal para instalaciones en altura. Incluye perno de anclaje químico y fijaciones de anclaje para un anclaje químico eficiente, sin complicaciones y que ahorra mano de obra.

Good Use ha estado ofreciendo a los clientes anclajes químicos de alta calidad certificados y probados, tanto con tecnología avanzada como con 25 años de experiencia. Good Use garantiza que se satisfagan las demandas de cada cliente.