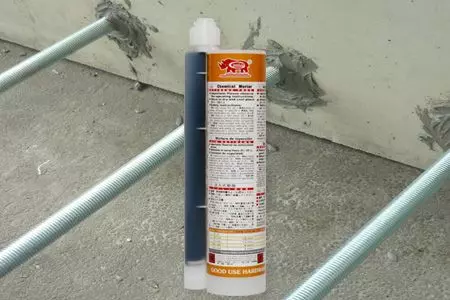

Anchor kimia vinilester injeksi bebas styrene 360ml untuk pemasangan di lingkungan korosif

GU-2000 360ml

Mortar kimia pengikat cepat kering

360ml Mortar Penambatan Kimia Vinylester – Sistem Kartrid Resin Pengeringan Cepat

GU-2000 360ml Mortar Pengikat Kimia Vinylester adalah salah satu sistem kartrid resin yang paling populer, dikenal karena kinerja dan fleksibilitasnya yang luar biasa. Waktu pengeringannya yang cepat menjadikannya solusi ideal untuk penambatan dalam berbagai aplikasi, seperti pagar pengaman, tangga, mesin, kanopi, gerbang, dan blok berongga yang terbuat dari beton, batu, atau bata pasir kapur padat. Sistem resin dua komponen 10:1 ini menawarkan pengaturan yang nyaman dan pengeringan yang cepat, bahkan pada suhu rendah, memastikan pemasangan yang andal dan efisien. Selain itu, ini adalah produk ramah lingkungan, bebas dari styrene dan VOC, memastikan keselamatan bagi pengguna dan dampak lingkungan yang rendah.

Diuji dan disetujui di Jerman sesuai dengan standar EAD 330499-00-0601, GU-2000 adalah pilihan terpercaya untuk para profesional. Rentang produk mencakup berbagai ukuran, termasuk 150ml, 235ml, 345ml, dan 380ml, untuk memenuhi berbagai permintaan pasar.

Sistem perbaikan kimia - Jangkar kimia vinylester yang cepat mengering

Salah satu fitur unggulan dari mortir hibrida vinilester kami adalah pengeringan cepatnya, yang secara signifikan mengurangi waktu pemasangan dan pengerasan. Kami telah mengembangkan berbagai formula pengeringan yang disesuaikan dengan kondisi iklim dan suhu pemasangan yang berbeda, memastikan kinerja optimal di berbagai lingkungan. Namun, formula pengeringan cepat tidak cocok untuk suhu tinggi ekstrem, karena ini dapat mempercepat proses pengeringan dan mempengaruhi kinerja. Untuk instalasi yang aman dan efektif, silakan merujuk pada lembar data teknis untuk pedoman rinci tentang kondisi instalasi dan waktu pengeringan.

Spesifikasi Jangkar Kimia Vinylester

● Bahan: Vinylester Tanpa Styrene

● Nomor Model: GU-2000

● Kapasitas: 360ml

● Rasio Campuran: 10:1

● Warna Campuran: Abu-abu

● Umur Simpan: 18 bulan

● Paket Standar: Satu kartrid dengan satu pengaduk

● Aksesoris Lain: Pengaduk, pistol sealant, selang nilon, pompa udara, kuas

Anchor Kimia Vinylester adalah Perekat Cepat Kering untuk Beton Kering

● Daya tahan dan keandalan tinggi

● Sistem perekat cepat kering

● Bebas styrene dan rendah VOC

● Ketahanan kimia yang sangat baik

● Cocok untuk pistol sealant 360ml

● Bahan bangunan ramah lingkungan

Selongsong Nylon dan Mortir Vinilester untuk Aplikasi Bata Berongga

Mortar Hibrida Vinylester GU-2000 dirumuskan khusus untuk aplikasi beban tinggi dan pengeringan cepat, serta merupakan solusi sempurna untuk memperbaiki bata berongga, unit pra-cetak, dan beton berlubang. Ketika digabungkan dengan selongsong nilon, sistem ini menawarkan kinerja yang lebih baik, terutama untuk instalasi di bahan berongga atau berpori, memberikan solusi yang andal dan fleksibel untuk aplikasi yang kompleks. Rangkaian luas dari selongsong nilon dirancang untuk bekerja secara mulus dengan mortir injeksi vinilester, memastikan bahwa titik jangkar tetap terpasang dengan aman. Kombinasi ini memaksimalkan kekuatan ikatan dan memastikan bahwa bahkan bahan ringan dan berongga mendapatkan manfaat dari daya tahan yang tinggi. Untuk elemen padat, mortir vinilester GU-2000 masih memberikan kekuatan ikatan yang sangat baik, menjadikannya solusi yang serbaguna untuk berbagai proyek konstruksi dan perbaikan. Baik dalam aplikasi residensial maupun komersial, sistem ini menjamin hasil berkinerja tinggi yang mampu bertahan dalam kondisi yang menuntut.

Bagaimana cara memasang jangkar kimia?

1. Bor Lubang: Mulailah dengan mengebor lubang sesuai dengan diameter dan kedalaman yang diperlukan sesuai dengan spesifikasi untuk jangkar. 2. Bersihkan Lubang: Hapus semua debu dan kotoran dari lubang menggunakan sikat dan pompa udara untuk memastikan permukaan bersih untuk ikatan yang optimal. 3. Siapkan Mortar: Tekan keluar mortar yang belum tercampur dari kartrid. Pastikan hanya mortir yang dicampur dengan benar yang digunakan untuk pemasangan. 4. Suntik Mortar: Suntik mortar yang telah dicampur ke dalam dasar lubang yang telah dibor, mengisinya secara merata. 5. Masukkan Jangkar: Masukkan dan putar besi tulangan, batang berulir, atau strip baja ke dalam lubang yang telah dibor. Hindari menyentuh atau mengganggu penyisipan jangkar sampai sepenuhnya mengering. *Catatan: Waktu penyembuhan tergantung pada suhu dan kondisi pemasangan lainnya. Rujuk ke Lembar Data Teknis (TDS) untuk informasi waktu pengeringan yang lebih rinci. Instalasi yang tepat sangat penting, karena setiap penyimpangan dalam proses dapat mempengaruhi kinerja pengikatan dari jangkar kimia.

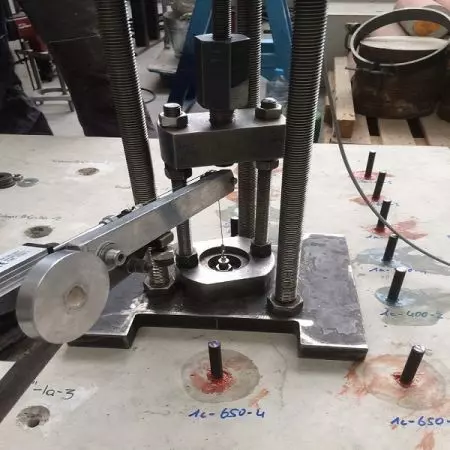

Semua Good Use Anchor Kimia - Disertifikasi oleh IWB Lab di Jerman dan CSTB Lab di Prancis

Saat ini, tidak ada laboratorium terakreditasi di Asia untuk menguji jangkar pengikat sesuai dengan standar Penilaian Teknis Eropa (ETA). Jangkar kimia kami menjalani pengujian menyeluruh sesuai dengan standar EAD 330087-01-6001 dan EAD 330499-00-0601 untuk pengikat batang baja dan batang ulir. Kami bekerja sama erat dengan para ahli terkemuka di Eropa yang memiliki lebih dari 20 tahun pengalaman di sektor pengikat. Dedikasi kami terhadap penelitian dan pengembangan mendorong peningkatan berkelanjutan dalam produk kami dan kemajuan sertifikasi internasional kami untuk jangkar kimia.

Data Teknis

DETAIL INSTALASI REBAR SUBSTRAT PADAT

| Tekanan |

Hancurkan Kekuatan Angkut (Kgf/KN) |

Keamanan Kekuatan Tarik (Kgf/KN) |

Standar Kerja (mm) |

||||||

| Kekuatan Beton | 4.000 psi | 280 kg/cm2 | 4.000 psi | 280 kg/cm2 | Diameter Lubang | Kedalaman Lubang | |||

| Nomor Rebar | #3 | (Φ10) | 3.540 | 35,8 | 1.180 | 11,9 | 13 | 90 | |

| #4 | (Φ13) | 5.490 | 55,4 | 1.827 | 18,5 | 16 | 120 | ||

| #5 | (Φ16) | 9,060 | 91.5 | 3,020 | 30.5 | 20 | 145 | ||

| #6 | (Φ19) | 14.150 | 142,9 | 4.717 | 47,6 | 25 | 170 | ||

| #7 | (Φ22) | 18.630 | 188,2 | 6.210 | 62,7 | 28 | 200 | ||

| #8 | (Φ25) | 23.195 | 234,3 | 7.732 | 78,1 | 32 | 225 | ||

| #9 | (Φ29) | 25.340 | 256,0 | 8.447 | 85,3 | 37 | 250 | ||

| #10 | (Φ32) | 32,120 | 324.4 | 10,707 | 108.1 | 40 | 290 | ||

| Catatan: | 1.Kekuatan Beton fc': 280kg/cm2 (4.000 psi) 2.Kekuatan Tulangan: #3~#5 fy: 2.800 kgf/cm2, #6~#11 fy= 4.200 kgf/cm2 |

||||||||

TABEL WAKTU PENGERINGAN

| Suhu (°C) | Penggellingan | Pengeringan Penuh |

| 5 | 90 menit. | 8 jam. |

| 10 | 40 menit. | 4 jam. |

| 20 | 18 menit. | 1,5 jam. |

| 30 | 9 menit. | 1 jam. |

| 40 | 6 menit. | 1 jam. |

| Silakan lakukan uji tarik setidaknya 24 jam setelah sepenuhnya sembuh. | ||

KONSUMSI PER KARTRID

| Ukuran Jangkar |

Diameter Lubang (mm) |

Kedalaman Lubang (mm) |

Jumlah Pemasangan | ||||

| 150ml | 235ml | 345ml | 360ml | 380ml | |||

| M8 | 10 | 80 | 30 | 47 | 69 | 72 | 76 |

| M10 | 12 | 90 | 18 | 29 | 42 | 44 | 47 |

| M12 | 14 | 110 | 11 | 17 | 25 | 27 | 28 |

| M16 | 18 | 125 | 6 | 9 | 14 | 14 | 15 |

| M20 | 24 | 170 | 2 | 4 | 6 | 6 | 6 |

| M24 | 28 | 210 | 1 | 2 | 3 | 4 | 4 |

| M30 | 35 | 270 | 1 | 1 | 2 | 2 | 2 |

| M36 | 40 | 330 | X | 1 | 1 | 1 | 1 |

| Catatan: Berdasarkan instalasi terus-menerus tanpa gangguan atau pergantian nozzle. Diberikan sebagai panduan dan akan bervariasi dengan suhu. | |||||||

- Produk TerkaitUnduhan BerkasPanduan InstalasiGaleri

Anchor kimia vinilester injeksi pengaturan cepat 150ml yang dirancang untuk penggunaan dalam ruangan

GU-2000 150ml

Jangkar Kimia Injeksi Vinylester 150ml untuk Aplikasi DIY Anchor kimia injeksi vinilester...

rincian235ml Pengikat kimia vinylester dua komponen untuk beban tinggi dan pemasangan kritis

GU-2000 235ml

235ml Vinylester Injeksi Mortar Jangkar Kimia Mortar jangkar kimia vinilester injeksi 235ml...

rincian345ml Mortir injeksi vinilester dengan penyusutan rendah untuk penguatan baja dalam beton

GU-2000 345ml

Anchor Kimia Vinylester 345ml – Ideal untuk Perbaikan Batang Berulir dan Besi Tulangan Anchor...

rincian380ml injeksi vinilester jangkar kimia dengan ketahanan kimia yang sangat baik untuk bahan semi-berongga

GU-2000 380ml

Anchor kimia vinilester yang mengeras cepat 380ml adalah solusi ideal untuk memperbaiki bata...

rincianPengikat kimia vinilester injeksi yang cepat mengering untuk instalasi pada suhu rendah

GU-2000 380ml

Anchor kimia vinylester adalah solusi ideal untuk aplikasi pengikatan perekat di cuaca dingin...

rincianPistol sealant perekat dua komponen serbaguna 360ml

#811N

#811N adalah dispenser multi-kompatibel untuk kartrid perekat 300/345/360ml dan beberapa pelanggan...

rincian

Anchor kimia vinilester injeksi bebas styrene 360ml untuk pemasangan di lingkungan korosif - Mortar kimia pengikat cepat kering | Dijual di 40 Negara Produsen Baut Kimia Injeksi Sejak 1997 | Good Use

Berlokasi di Taiwan sejak 1997, Good Use Hardware Co., Ltd. telah menjadi produsen mortir dan jangkar perekat injeksi. Produk utama mereka, termasuk jangkar kimia vinilester injeksi bebas stirena 360ml untuk perbaikan di lingkungan korosif, kartrid injeksi, mortir kimia, jangkar kimia, kapsul jangkar, resin poliester, dan resin vinilester, yang dijual di 40 negara.

Pabrik yang terpercaya dari baut kimia di Taiwan menghasilkan berbagai solusi perekat baut terluas untuk aplikasi penancapan beton Anda. dengan pengalaman manufaktur lebih dari 15 tahun untuk Sistem Anchor Kimia, Sistem Kartu Injeksi, Mortar Bahan Kimia Konstruksi, dan lainnya. Solusi penambat kimia bersertifikat dengan berbagai pilihan bahan perekat termasuk penambat epoksi, penambat beton, penambat resin untuk beban berat dalam aplikasi tulangan, lubang bor berlian, dan penambatan dalam beton padat. Formula anti-tetes, ideal untuk pemasangan di atas kepala. Baut pengikat kimia dan perlengkapan pengikat termasuk untuk pengencangan kimia yang efisien, mudah, dan menghemat tenaga kerja.

Good Use telah menawarkan kepada pelanggan chemical anchor berkualitas tinggi yang telah teruji dan bersertifikat, baik dengan teknologi canggih maupun pengalaman selama 25 tahun, Good Use memastikan setiap permintaan pelanggan terpenuhi.