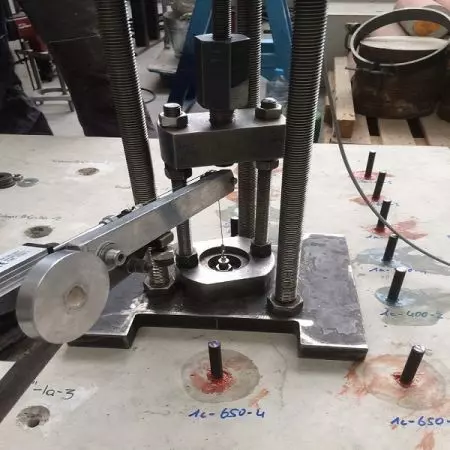

Anchor kimia epoxy injeksi yang disetujui ETA dirancang untuk retrofitting batang dowel

GU-500SD 400ml 3:1

Mortar Anchor Kimia Epoxy Injeksi Dirancang untuk Digunakan di Beton Basah

Anchor kimia epoxy murni GU-500SD telah berhasil menerima laporan Penilaian Teknis Eropa ETA-24/0928, yang mengonfirmasi kinerja tinggi dan keandalannya untuk aplikasi struktural. Penilaian dilakukan sesuai dengan EAD 330087-01-0601, mencakup berbagai kondisi termasuk lingkungan alkalinitas tinggi, atmosfer belerang, ketahanan korosi, dan kinerja paparan api.

Anchor kimia epoxy murni berkinerja tinggi ini dirancang khusus untuk sambungan rebar dan pengikatan berat di beton kering, basah, dan tidak retak. Formulasi canggihnya memberikan kekuatan ikatan yang luar biasa dan daya tahan jangka panjang di berbagai rentang suhu, menjadikannya pilihan yang dapat diandalkan bahkan untuk aplikasi struktural yang paling menuntut. Disertifikasi dan diuji kualitas oleh laboratorium terakreditasi di Jerman dan Prancis, jangkar kimia epoksi GU-500SD memiliki konsistensi yang tidak melorot, memungkinkan pemasangan yang bersih dan efektif pada aplikasi yang dipasang di atas kepala atau secara vertikal, seperti langit-langit dan soffit. Untuk fleksibilitas tambahan di lokasi kerja, GU-500SD juga tersedia dalam kartrid 585ml, ideal untuk tugas penambatan skala besar atau berkelanjutan.

Sistem Perbaikan Kimia - Jangkar Epoxy Murni Kinerja Terbaik

Mortar epoksi berkinerja tinggi yang dirancang untuk pengikatan berat. Anchor kimia canggih ini ideal untuk aplikasi yang memerlukan kinerja superior untuk memastikan pengikatan yang aman dalam kondisi kritis, variasi suhu, atau batasan instalasi. Diuji dalam berbagai skenario pengikatan di laboratorium yang disetujui ETAG, kami menyediakan laporan perbandingan untuk menunjukkan kemampuannya. Anchor perekat injeksi epoksi kami adalah salah satu pengikat terkuat yang tersedia, memenuhi permintaan yang terus meningkat untuk solusi pengikatan yang dapat diandalkan.

Spesifikasi Jangkar Kimia Epoxy Murni Terbaik

● Bahan: Epoxy Murni

● Nomor Model: GU-500SD

● Kapasitas: 400ml

● Rasio Pencampuran: 3:1

● Warna Pencampuran: Oranye

● Umur Simpan: 18 bulan

● Paket Standar: Satu kartrid dengan satu pengaduk

● Aksesori Lain: Pengaduk, pistol sealant, selang nilon, pompa udara, kuas

Paku kimia epoxy murni cocok untuk bekerja dalam rentang suhu yang luas

● Dapat digunakan pada suhu rendah dan tinggi

● Tersedia untuk pemasangan lubang beton basah (Pengurangan beban yang direkomendasikan sebesar 20%)

● Beban berat

● Tidak melorot untuk aplikasi atap dan dinding

● Kinerja baik pada pengencangan kritis

● Ideal untuk penanaman dalam dan lubang besar

● Tidak ada penyusutan

● Bebas styrene, rendah bau, dan diuji LEED untuk VOC (Senyawa Organik Volatil)

● Tidak ada masalah kesehatan atau keselamatan yang menghambat pekerjaan Anda

● Sertifikat ETA-24/0928

● Mencapai umur layanan 50 tahun

Epoksi Kimia Non-Sag untuk Penambatan Cuaca Dingin

Mortar epoxy murni berkekuatan tinggi kami memberikan kinerja luar biasa untuk sambungan rebar dan pengikatan berat, bahkan dalam kondisi cuaca dingin. Cocok untuk digunakan sepanjang tahun di semua musim, juga mudah disimpan. Untuk lingkungan yang sangat dingin, kami merekomendasikan mempertimbangkan bahan vinilester, atau Anda dapat menghubungi kami untuk formula yang disesuaikan dengan kebutuhan spesifik Anda. Ini memastikan kinerja pengikatan yang dapat diandalkan, tidak peduli suhu.

Mortar Suntik Epoksi untuk Penambatan di Beton Basah

Epoxy berkualitas tinggi kami dirancang untuk memenuhi semua kebutuhan pengikatan dan perbaikan, menawarkan kinerja yang dapat diandalkan bahkan dalam kondisi yang menantang. Epoxy GU-500SD dapat dipasang dengan sukses di beton basah, memberikan hasil pengikatan yang sangat baik. Namun, harap dicatat bahwa kekuatan ikatan mungkin lebih rendah dibandingkan dengan pemasangan di beton kering. Kami memiliki laporan kinerja dari laboratorium terkemuka yang tersedia untuk referensi Anda. Jangan ragu untuk menghubungi kami untuk informasi lebih lanjut.

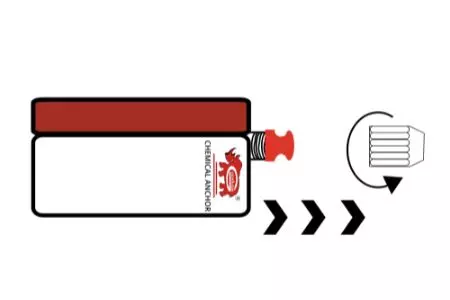

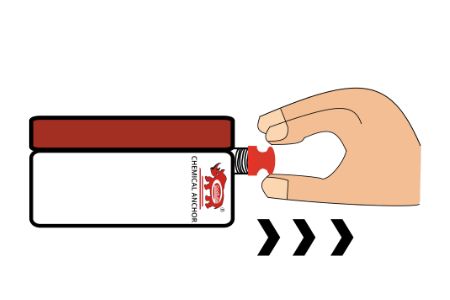

Bagaimana Cara Menggunakan Pistol Caulk Anchor Kimia?

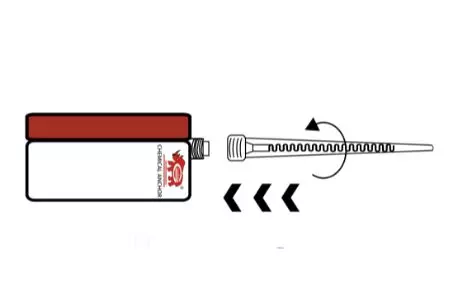

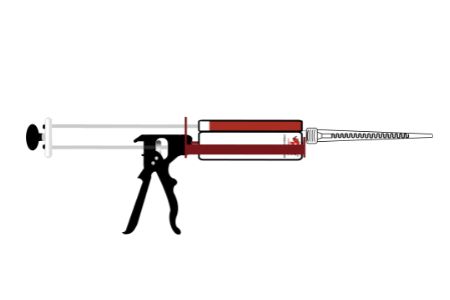

1. Lepaskan Batang Baja: Temukan pemicu kecil di bagian belakang pistol sealant. Tekan pemicu pelepas dengan ibu jari Anda untuk melonggarkan batang baja panjang yang berjalan melalui rangka. 2. Tarik Kembali Piston: Tarik piston sepenuhnya ke belakang untuk mempersiapkan senjata untuk digunakan. 3. Siapkan Tabung: Lepaskan tutup putih dan colokan dari tabung. Selanjutnya, pasang nozzle mixer ke tabung. Masukkan ujung datar tabung ke belakang pistol sealant, dengan tabung dan nosel pengaduk diposisikan di depan. 4. Muat Tabung: Tarik pemicu pegangan untuk menggerakkan plunger dari pistol sealant. Pastikan plunger sejajar dengan piston tabung dengan benar. Posisi tabung yang benar sangat penting untuk aplikasi yang tepat. Dengan mengikuti langkah-langkah ini, Anda dapat memastikan penggunaan pistol caulking anchor kimia yang lancar dan efektif.

Good Use Pengikat Kimia - Disetujui oleh Laboratorium IWB di Jerman dan Laboratorium CSTB di Prancis

Saat ini, tidak ada laboratorium terakreditasi di Asia yang dilengkapi untuk menguji jangkar pengikat sesuai dengan standar Penilaian Teknis Eropa (ETA). Untuk memastikan kualitas dan kepatuhan tertinggi, jangkar kimia kami diuji secara ketat sesuai dengan EAD 330087-01-0601 dan EAD 330499-00-0601, mencakup aplikasi untuk pengikat batang baja dan batang ulir. Produk unggulan kami, jangkar kimia epoksi GU-500SD, telah secara resmi disetujui oleh ETA berdasarkan standar EAD 330087-01-0601, yang memverifikasi kinerjanya di bawah persyaratan ketat Eropa. Kami bekerja sama secara erat dengan para ahli terkemuka Eropa yang memiliki lebih dari 20 tahun pengalaman di industri pengikat dan penambatan. Kemitraan ini, dipadukan dengan fokus kuat kami pada penelitian dan pengembangan, memastikan inovasi produk yang berkelanjutan dan perluasan terus-menerus dari sertifikasi internasional kami untuk solusi pengikatan kimia.

Data Teknis

DETAIL INSTALASI REBAR SUBSTRAT PADAT

| Tekanan | Kekuatan Angkut Hancur (Kgf/KN) | Kekuatan Angkut Aman (Kgf/KN) | Standar Kerja (mm) | ||||||

| Kekuatan Beton | 4.000 psi | 280 kg/cm2 | 4.000 psi | 280 kg/cm2 | Diameter Lubang | Kedalaman Lubang | |||

| Besi Tulangan No. | #3 | (Φ10) | 3.622 | 36,6 | 1.207 | 12,2 | 13 | 90 | |

| #4 | (Φ12) | 6.437 | 65,0 | 2.146 | 21,7 | 16 | 125 | ||

| #5 | (Φ16) | 9.737 | 98,4 | 3.246 | 32,8 | 20 | 145 | ||

| #6 | (Φ20) | 13.715 | 138,5 | 4.572 | 46.2 | 25 | 170 | ||

| #7 | (Φ22) | 18,754 | 189.4 | 6,215 | 63.1 | 28 | 200 | ||

| #8 | (Φ25) | 24.137 | 243,8 | 8.046 | 81,3 | 32 | 225 | ||

| #9 | (Φ28) | 27.484 | 277,6 | 9.161 | 92,5 | 37 | 260 | ||

| #10 | (Φ32) | 31.869 | 321.9 | 10.623 | 107.3 | 40 | 290 | ||

| #11 | (Φ36) | 36.000 | 363.6 | 12.000 | 121.2 | 42 | 320 | ||

| Catatan: | 1.Kekuatan Beton fc': 280kg/cm2 (4.000 psi) 2.Kekuatan Tulangan: #3~#5 fy: 2.800 kgf/cm2, #6~#11 fy= 4.200 kgf/cm2 |

||||||||

TABEL WAKTU PENGERINGAN

| Suhu (°C) | Penggellingan | Pengeringan Penuh |

| 5~9 | 2 jam. | 90 jam. |

| 10~14 | 90 menit. | 64 jam. |

| 15~19 | 45 menit | 28 jam |

| 20~29 | 30 menit | 18 jam |

| 30~39 | 20 menit | 7 jam |

| 40 | 12 menit | 5 jam. |

| Silakan lakukan uji tarik selama setidaknya 24 jam setelah sepenuhnya sembuh. | ||

KONSUMSI PER KARTUS YANG DITETAPKAN

| Ukuran Jangkar |

Diameter Lubang (mm) |

Kedalaman Lubang (mm) |

Jumlah Pemasangan |

| 400ml | |||

| M8 | 10 | 80 | 80 |

| M10 | 13 | 90 | 42 |

| M12 | 16 | 120 | 21 |

| M16 | 20 | 145 | 11 |

| M20 | 25 | 170 | 6 |

| M24 | 28 | 210 | 4 |

| M30 | 35 | 270 | 2 |

| M36 | 40 | 330 | 1 |

| Catatan: Berdasarkan pemasangan terus menerus tanpa gangguan atau perubahan nosel. Disediakan sebagai panduan dan akan bervariasi dengan suhu. | |||

- Produk TerkaitUnduhan BerkasPanduan InstalasiGaleri

400ml jangkar kimia epoksi yang dirancang untuk digunakan dalam kondisi cuaca tropis

GU-500 400ml 3:1

Anchor kimia epoxy 400ml ini, dalam kartrid injeksi 3:1, dirancang untuk sambungan rebar dan pengikatan...

rincian650ml perekat epoxy untuk pemasangan suhu tinggi

GU-500 650ml 1:1

Mortar injeksi berbasis epoksi dengan rasio 1:1 dan kapasitas 650ml ini ideal untuk proyek...

rincianPerekat Kimia Epoksi Kekuatan Tinggi yang Disetujui ETA untuk Sistem Pemasangan Beton

GU-500SD 585ml 3:1

GU-500SD adalah solusi pengikatan epoxy murni berkinerja tinggi yang disetujui ETA, dirancang...

rincianSenapan caulking epoxy resin dua komponen standar 400ml

#810

Aplikasi caulking manual #810 adalah dispenser yang ekonomis dan dapat diandalkan, dirancang...

rincianSenapan aplikator epoksi cartridge premium 400ml berdampingan

G34-400LA

G34-400LA adalah dispenser manual 2-komponen yang berat, dirancang khusus untuk kartrid epoksi...

rincianNozzle pencampur untuk jangkar kimia 1:1 dan 3:1

#818

Nozel mixer statis digunakan pada kartrid perekat untuk mencampur dan menyuntikkan perekat...

rincian

Anchor kimia epoxy injeksi yang disetujui ETA dirancang untuk retrofitting batang dowel - Mortar Anchor Kimia Epoxy Injeksi Dirancang untuk Digunakan di Beton Basah | Dijual di 40 Negara Produsen Baut Kimia Injeksi Sejak 1997 | Good Use

Berlokasi di Taiwan sejak 1997, Good Use Hardware Co., Ltd. telah menjadi produsen mortir dan jangkar perekat injeksi. Produk utama mereka, termasuk jangkar kimia epoxy injeksi yang disetujui ETA yang dirancang untuk retrofitting batang dowel, kartrid injeksi, mortir kimia, jangkar kimia, kapsul jangkar, resin poliester, dan resin vinilester, yang dijual di 40 negara.

Pabrik yang terpercaya dari baut kimia di Taiwan menghasilkan berbagai solusi perekat baut terluas untuk aplikasi penancapan beton Anda. dengan pengalaman manufaktur lebih dari 15 tahun untuk Sistem Anchor Kimia, Sistem Kartu Injeksi, Mortar Bahan Kimia Konstruksi, dan lainnya. Solusi penambat kimia bersertifikat dengan berbagai pilihan bahan perekat termasuk penambat epoksi, penambat beton, penambat resin untuk beban berat dalam aplikasi tulangan, lubang bor berlian, dan penambatan dalam beton padat. Formula anti-tetes, ideal untuk pemasangan di atas kepala. Baut pengikat kimia dan perlengkapan pengikat termasuk untuk pengencangan kimia yang efisien, mudah, dan menghemat tenaga kerja.

Good Use telah menawarkan kepada pelanggan chemical anchor berkualitas tinggi yang telah teruji dan bersertifikat, baik dengan teknologi canggih maupun pengalaman selama 25 tahun, Good Use memastikan setiap permintaan pelanggan terpenuhi.