Products

Chemical Anchors - Reliable Solutions for Structural Connection and Reinforcement

Chemical anchors provide high-performance solutions for connecting, extending, and reinforcing both new and existing concrete structures from residential buildings to bridges. Ideal for elements like walls, beams, columns, and slabs, they offer superior flexibility through post-installed rebar systems compared to cast-in-place methods. Suitable for everything from home repairs to major infrastructure projects, chemical anchors deliver strength, reliability, and versatile applications.

How to Distinguish the Quality of a Chemical Anchor?

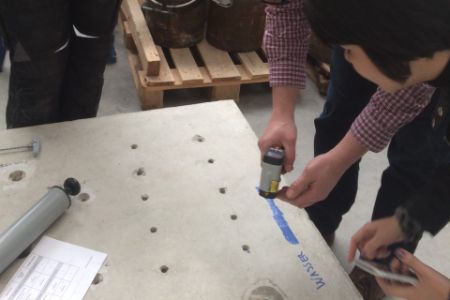

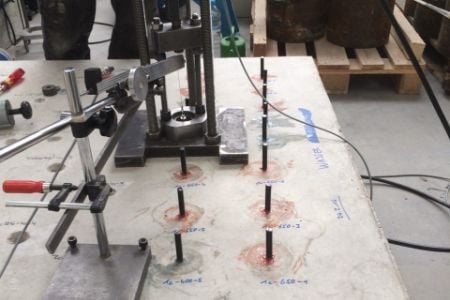

When it comes to chemical anchors, bond strength is a key performance indicator, often delivering superior load values compared to traditional mechanical fasteners. Manufacturers typically provide bond strength tables or test reports issued by accredited laboratories as performance references. However, it's important to note that real-world conditions such as varying weather, concrete quality, hole cleaning practices, and installer experience can all impact the final anchoring performance. That is why the overall quality of a chemical anchor system depends not only on the adhesive itself but also on the correct installation procedure, the suitability of the product for the environment, reliable testing equipment, and the skill level of the installer.

Among the top-performing products in the market, our GU-500SD stands out with its newly obtained ETA 24/0928 certification. This European Technical Assessment confirms that GU-500SD meets the standards for load performance, fire resistance, alkali and corrosion resistance, and durability in sulfur-rich environments. Certified for a service life of 50 years and operable within a wide temperature range of -40°C to +67°C, GU-500SD offers proven reliability under real construction site conditions. Choosing a certified and thoroughly tested adhesive not only ensures structural integrity but also minimizes risks on-site, making it a smart and secure investment for any critical anchoring application.

How to Choose the Right Chemical Anchor?

Selecting the right chemical anchoring system depends on several key factors, including the application type, installation conditions, and environmental exposure. A well-matched adhesive ensures optimal performance, safety, and durability over time. For example, in tropical or high-temperature regions, a slow-curing epoxy is often preferred to provide sufficient working time during installation. In contrast, cold climates require fast-curing adhesives that can set and achieve high bond strength even at low temperatures. Other considerations include load requirements, base material conditions (such as cracked or uncracked concrete), installation direction (overhead, vertical, or horizontal), and exposure to chemicals, moisture, or high alkalinity.

To ensure maximum anchoring performance, it is crucial to select a product that meets international standards and has been tested for real-world conditions. For general anchoring applications, our GU-100 polyester, GU-600 epoxy acrylate, and GU-2000 vinylester chemical anchors offer reliable performance and excellent value across a wide range of construction needs. For structurally critical or safety-sensitive projects, we recommend our high-performance GU-500SD injection epoxy mortar, which is certified with ETA 24/0928, ensuring compliance with stringent European standards for strength, durability, and long-term reliability. If still not sure which product fits your project? Share your project requirements with us, and we will guide you in selecting the most effective and reliable anchoring solution.

GU-100 Polyester Injectable Chemical Anchor

Polyester chemical anchors are widely used in the construction industry due to their versatility. They...

GU-500 Pure Epoxy Injectable Chemical Anchor

Epoxy chemical anchors offer excellent stability and superior bonding performance, making them suitable...

GU-600 Epoxy Acrylate Injectable Chemical Anchor

Epoxy acrylate chemical anchors are widely used in civil engineering due to their high bonding strength,...

GU-2000 Vinylester Injectable Chemical Anchor

The Vinylester chemical anchor is a fast-curing anchoring resin, designed for quick setting, particularly...

Epoxy Can System For Repair Works

Epoxy resin is useful filler, sealer, and adhesive and it is easy to use. Resins and hardeners are packed...

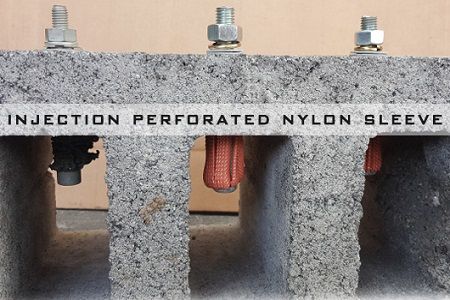

Nylon Sleeve For Hollow Brick

Nylon sleeve is designed to hold anchor bolt and chemical anchor in perforated substrate which is a non-expansion...

Caulking Gun

Caulking guns are designed to hold the cartridge securely and provide a smooth, controlled and straight...

Mixing Nozzle and Drilled Hole Cleaning Tools

To have a successful chemical anchor installation, a good performance chemical anchor and the accessory...