Chemical Anchor For Granites fixing On Building Facades

Faster curing vinylester chemical anchors for fixing external wall cladding

We had received a request from an Indian contracting firm which is involved in interior and exterior building finishes. They want to install stone panels on building facades, so fast hardening chemical anchors with quick loads capacity is required for the installation. We customized the formula of GU-2000 vinylester resin, the working time and fully hardening time is just 3 mins and 30 mins at temperature 30-40 degree. It provides less waiting time and sufficient strength to hold the stone cladding bracket.

Chemical anchoring for cladding bracket is stronger than mechanical fixing

Mechanical fixing and chemical fixing are common techniques for building facades installation. To fix cladding system, mechanical fixing is directly fastening with expansion bolt or hammer drive anchor. To consider the loading weight and long-term bearing last, anchoring the cladding bracket with chemical resin is stronger and safer. By using injection vinylester hybrid mortar to fastener rebar #3, diameter 10 can sustain roughly 885kg on 3,000psi concrete. The result is superior than using expansion bolts.

- Related Products

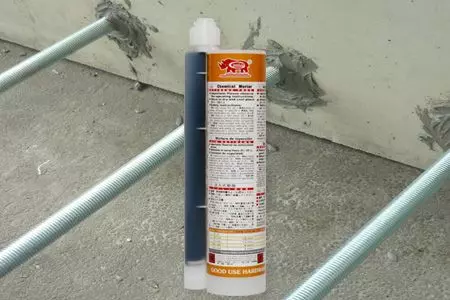

345ml Low-shrink injection vinylester chemical anchor for reinforcing steel in concrete

GU-2000 345ml

345ml Vinylester Chemical Anchor – Ideal for Threaded Rod and Rebar FixingThe 345ml vinylester chemical anchor is specifically designed for fixing...

Details360ml Styrene-free injection vinylester chemical anchor for fixing in corrosive environments

GU-2000 360ml

360ml Vinylester Chemical Anchoring Mortar – Fast Curing Resin Cartridge SystemGU-2000 360ml Vinylester Chemical Anchoring Mortar is one of the most...

Details380ml Injection vinylester chemical anchor with excellent chemical resistance for semi-hollow materials

GU-2000 380ml

The 380ml fast hardening vinylester chemical anchor is an ideal solution for fixing hollow bricks using anchor sleeves. It is commonly referred to as a 400ml...

Details