How can I store partially used chemical anchor cartridges? Can they be reused later?

Yes, partially used Good Use chemical anchor cartridges can be reused if they are properly stored and handled after initial use. Careful cleaning and sealing are essential to prevent resin curing inside the nozzle and to maintain the quality of the remaining material.

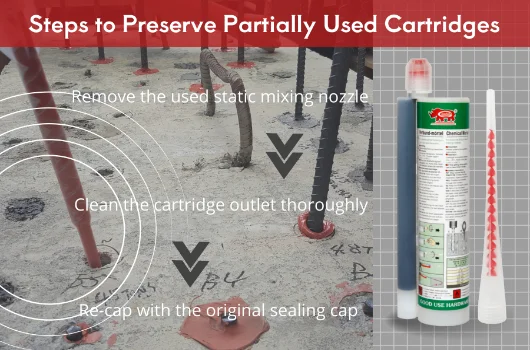

➤ Steps to Preserve Partially Used Cartridges:

1. Remove the used static mixing nozzle: The mixed resin inside the nozzle will begin curing within minutes, if not removed promptly, the cured resin may block the cartridge outlet, making it impossible to dispense the next time.

2. Clean the cartridge outlet thoroughly: Use a clean cloth or paper towel to wipe off any residual resin from the nozzle tip. If hardened resin is present, gently scrape it away using a utility knife. Avoid striking or squeezing the cartridge.

3. Re-cap with the original sealing cap or dust cover: Ensure the cap is tightly sealed to prevent air or moisture exposure. For added protection, place a clean sheet of paper inside the cap to absorb any remaining residue.

➤ Storage Conditions After Opening:

• Keep in a temperature range of 15°C to 25°C (59°F to 77°F): Avoid storing in high heat or freezing temperatures, which can damage the resin.

• Store in a cool, dry place away from sunlight: Direct exposure to UV or humidity may accelerate resin deterioration.

• Label the cartridge with the date of first use: Helps apply FIFO (first in, first out) inventory control and track usability.

➤ How to Reuse the Cartridge:

• Install a new static mixing nozzle.

• Dispense and discard the first 10~20 cm (approx. 4–8 inches) of resin to ensure proper mixing.

• Check resin consistency, if it flows smoothly with the correct color and texture, it is safe to proceed.

• If the cartridge was opened over 3~6 months ago, we recommend conducting a gel test or pull-out test prior to application.

All Good Use chemical anchor cartridges are clearly marked with expiry dates. Even partially used cartridges should be handled with the same care as new ones to ensure anchoring strength and structural safety. If you are unsure about the condition of remaining resin, please contact our team for guidance.

- Chemical Anchor Showcase

345ml Durable polyester chemical anchor for concrete fixing

GU-100 345ml

The 345ml polyester chemical anchor is a medium-sized option that offers flexibility in the market....

Details400ml Epoxy chemical anchor designed for use in tropical weather conditions

GU-500 400ml 3:1

This 400ml epoxy chemical anchor, in a 3:1 injectable cartridge, is designed for rebar connections...

DetailsETA approved high-strength epoxy chemical anchor for concrete mounting systems

GU-500SD 585ml 3:1

GU-500SD is our ETA-approved, high-performance pure epoxy anchoring solution, specifically...

Details380ml Heavy load epoxy acrylate chemical anchor for safety-critical fixing applications

GU-600 380ml

The 380ml epoxy acrylate chemical anchor comes in a coaxial cartridge design, requiring a special...

Details235ml Two component vinylester chemical anchor for high loads and critical fixings

GU-2000 235ml

235ml Vinylester Injection Chemical Anchor Mortar The 235ml vinylester injection chemical...

Details