How do I properly install and use a chemical anchor (injection mortar)?

A correct installation process is essential to ensure the bonding strength and overall safety of a chemical anchoring system. Unlike general adhesives, chemical anchors require precise application to achieve optimal performance. Below are the five key installation steps recommended by Good Use, suitable for various base materials including concrete, brick, and stone.

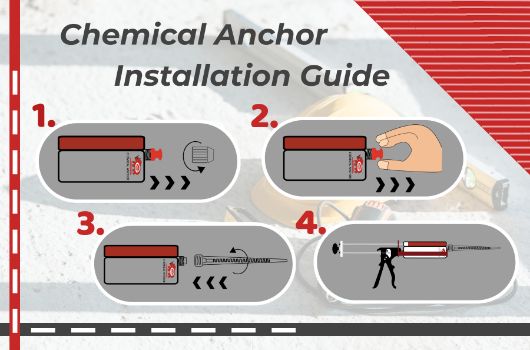

➤ Step-by-Step Installation Guide

Step 1: Drilling the Hole

• Drill the hole in the base material (concrete, brick, stone, etc.) to the specified diameter and depth based on the anchor size.

• For hollow base materials, use nylon sleeves to retain the resin and support the anchor rod.

Step 2: Cleaning the Hole

• Blow out the dust using a blow-out-pump or air compressor.

• Brush the hole with a steel brush to remove loose particles and debris.

• Blow again to ensure the hole is completely clean and dry.

• Repeat the blow-brush-blow cycle at least twice for best results.

This is one of the most critical steps. Poor cleaning = weak bonding!

Step 3: Injecting the Resin

• Attach the static mixing nozzle to the cartridge and start dispensing.

• Discard the first 10~20cm (4~8 inches) of extruded resin, which may not be fully mixed.

• Inject resin from the bottom of the hole upward, pulling the nozzle out slowly to avoid air gaps.

• Fill about 2/3 to 3/4 of the hole with resin.

Step 4: Inserting the Anchor Rod

• Insert the threaded rod, rebar, or bolt with a slow, twisting motion to ensure full contact between resin and steel.

• Do not move or remove the anchor after insertion.

Step 5: Curing Time

• Refer to the product's technical data sheet (TDS) for gel and full curing times.

• Do not apply any load or stress to the anchor until it has fully cured.

• In colder conditions, curing may take longer. Always verify based on the resin's specifications.

How to Use Chemical Anchors - Proper Installation Is Key to Safety and Performance

Correct handling and installation of chemical anchors is not just about construction quality. It directly impacts the long-term safety and structural integrity of your project. Watch our installation video to learn the essential steps, best practices, and expert tips to ensure a successful anchoring process.

➤ Recommended Tools

• Blow-out pump or compressed air for hole cleaning.

• Steel brush for debris removal.

• High-thrust manual or pneumatic dispenser (match cartridge size).

• Gloves, goggles, and proper personal protective equipment.

We strongly recommend conducting a trial installation or pull-out test under actual jobsite conditions to verify the performance before full-scale application, especially in the following situations:

• Cold or hot environments

• Wet or damp substrates

• Hollow base materials

• Structural or seismic-critical projects

If you are unsure which chemical anchor is most suitable for your application, please contact our team for expert assistance.

- Chemical Anchor Showcase

360ml Certified polyester chemical anchor for construction projects

GU-100 360ml

The 360ml polyester chemical anchor is a medium-sized option that offers greater flexibility...

Details400ml Epoxy chemical anchor designed for use in tropical weather conditions

GU-500 400ml 3:1

This 400ml epoxy chemical anchor, in a 3:1 injectable cartridge, is designed for rebar connections...

Details650ml Epoxy anchoring adhesive for high-temperature installations

GU-500 650ml 1:1

This 650ml, 1:1 ratio, slow-cure epoxy-based injection mortar is ideal for anchoring projects...

Details345ml Premium quality epoxy acrylate chemical anchor for multiple fixing applications

GU-600 345ml

The 345ml epoxy acrylate chemical anchor is a popular medium-sized option for a wide range...

Details345ml Low-shrink injection vinylester chemical anchor for reinforcing steel in concrete

GU-2000 345ml

345ml Vinylester Chemical Anchor – Ideal for Threaded Rod and Rebar FixingThe 345ml vinylester...

Details