What can go wrong if the injection mortar is not fully mixed?

When opening a new cartridge of chemical anchor, it is critical to discard the first 10~20cm (approximately 4~8 inches) of extruded material. This initial portion may not be properly mixed and should never be used for installation, as it can resuit in anchoring failure and serious structural risks.

Chemical anchor is a two-component system composed of resin and hardener. These components must be thoroughly blended inside the static mixing nozzle to achieve a complete chemical reaction and form a strong, durable bond. If the material is inadequately mixed, the performance and safety of the anchoring system may be severely compromised.

Potential Risks of Using Unmixed Mortar

Reduced Load Capacity

Even if hardened, incomplete chemical reactions can significantly weaken the anchoring strength.

Structural Safety Risk

In critical or seismic applications, improper anchoring can result in structural failure.

Difficult to Detect

Incomplete mixing may not be visible, and problems are usually discovered during pull-out testing or actual use.

Best Practices for Proper Mixing

• Always install the static mixing nozzle before dispensing.

• Purge and discard the first 10~20cm of extruded material from the nozzle.

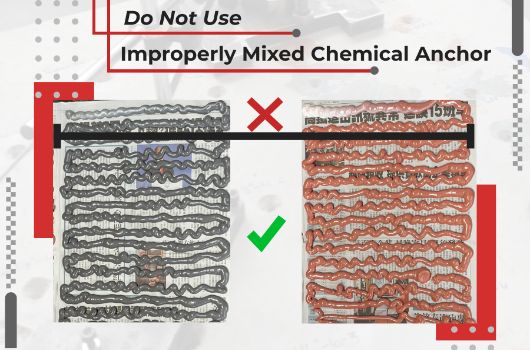

• Check for consistent color and texture. Any streaking, separation, or dual-color output indicates poor mixing.

• Confirm that the curing time aligns with product's technical data sheet.

Even a small oversight in the mixing step can compromise the entire anchoring system. If you encounter unusual resin flow, color inconsistency, or curing issues, contact our team immediately. We offer full product documentation and expert support to ensure safe and reliable application of every cartridge.

- Chemical Anchor Showcase

345ml Durable polyester chemical anchor for concrete fixing

GU-100 345ml

The 345ml polyester chemical anchor is a medium-sized option that offers flexibility in the market....

Details400ml Epoxy chemical anchor designed for use in tropical weather conditions

GU-500 400ml 3:1

This 400ml epoxy chemical anchor, in a 3:1 injectable cartridge, is designed for rebar connections...

DetailsETA approved injection epoxy chemical anchor designed for dowel bar retrofitting

GU-500SD 400ml 3:1

GU-500SD pure epoxy chemical anchor has successfully received the European Technical Assessment...

Details360ml High bond strength epoxy acrylate chemical anchor for vertical and horizontal fixing

GU-600 360ml

The 360ml epoxy acrylate chemical anchor is a top-selling option for general fixations and reinforcement...

Details380ml Injection vinylester chemical anchor with excellent chemical resistance for semi-hollow materials

GU-2000 380ml

The 380ml fast hardening vinylester chemical anchor is an ideal solution for fixing hollow...

Details