High viscosity epoxy can system for repair works

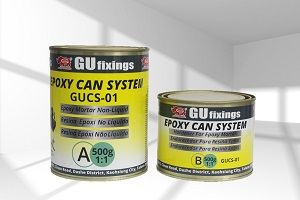

GUCS-01

1:1 two-part non liquid epoxy mortar

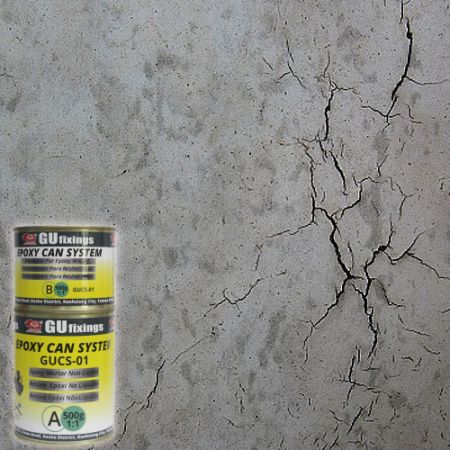

Epoxy structural adhesive is wide using for concrete repair. When mix the resin and hardener, thick epoxy mortar is formed. Thus epoxy resin is perfect for repair cracks or holes in the areas that required poor flowability, such like edges and corners. Excellent adhesion bond with the surface of concrete and steels.

Specification Of High Viscosity Epoxy Can System

● Model number: GUCS-01

● Material: Epoxy resin

● Resin color: White

● Hardener color: Black

● Capacity: 500g(resin) + 500g(hardener)

● Mixing Ratio: 1:1

● Mixed Color: Gray

● Shelf Life: 18 months

Epoxy resin can system is high loading adhesive

● Styrene free construction material

● Provide longer working time

● High loading adhesive

● No wastage, just take needed consumption and mix

● Available for wild range of applications

● No caulking gun required

● Excellent quality with multiple tests report by SGS

Application Of GUCS-01 High Viscosity Epoxy Can System

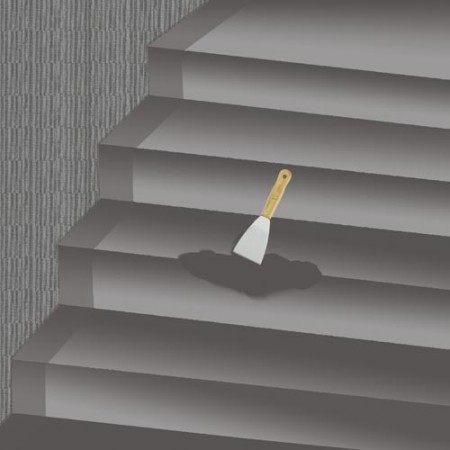

● Reconstruction of edges and corners

● Fixing reinforcement bars, wooden constructions, machines, and dry screw

● Repair works for tiles, brick, concrete, and steel

● Easy to use for DIY or professional applications

● ECO friendly adhesive and waterproof

- Related Products

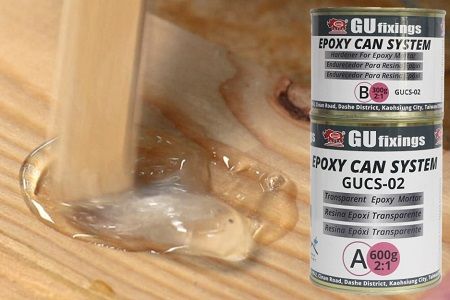

Transparent epoxy resin for bonding parts

GUCS-02

Clear resin can be glued with most of materials. Due to its strong bond, it can be used as an adhesive...

DetailsLow viscosity epoxy can system for filling cracks

GUCS-03

Liquid epoxy mortar can be poured into holes or cracks directly or used with a brush. It ideally...

Details- Files Download

Epoxy Can System Catalogue

The epoxy can system is a user-friendly solution for repair and bonding. Good Use offers three types, with more applications in the catalog.

Download- Gallery

High viscosity epoxy can system for repair works - 1:1 two-part non liquid epoxy mortar | Sold in 40 Countries Injectable Chemical Anchors Manufacturer Since 1997 | Good Use

Located in Taiwan since 1997, Good Use Hardware Co., Ltd. has been an injectable adhesive mortars and anchors manufacturer. Their main products, including High viscosity epoxy can system for repair works, injection cartridges, chemical mortars, chemical anchors, anchor capsules, polyester resins and vinylester resins, which are sold in 40 countries.

Reputable factory of chemical anchor in Taiwan produces the widest range of adhesive anchor solutions for your concrete anchoring applications. with more than 15 years manufacturing experience for Chemical Anchor System, Injection Cartridge System, Construction Chemical Mortar and more. Certified chemical anchor solutions with wide selections of adhesive materials including epoxy anchors, concrete anchors, resin anchors for heavy loads in rebar application, diamond drilled holes and anchoring in solid concrete. Non-drip formula, ideal for overhead installation. Chemical anchor bolt and anchor fixings included for efficient, hassle-free, labor-saving chemical anchoring.

Good Use has been offering customers certified and tested high-quality chemical anchors, both with advanced technology and 25 years of experience, Good Use ensures each customer's demands are met.