What is chemical anchor?

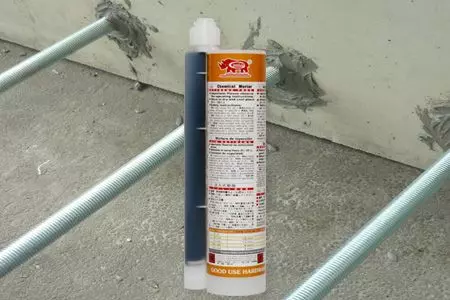

A chemical anchor is a type of fastener used to secure objects into concrete, masonry, or other solid materials using a chemical adhesive instead of mechanical expansion. It consists of a resin-based adhesive (such as epoxy, polyester, or vinyl ester) and a metal anchor (like a threaded rod or rebar).

Benefits of Chemical Anchors vs. Traditional Expansion Anchors

Superior Bonding & Waterproofing

Chemical anchors create a chemical bond between the steel and concrete by filling all irregularities within the drilled hole. This results in: 100% adhesion for a stronger, more uniform bond. Airtight and waterproof seal, preventing moisture penetration and corrosion. In contrast, mechanical expansion anchors rely on friction and expansion forces, which do not seal the hole completely, leaving gaps that can allow water ingress and corrosion over time.

Higher Load Capacity & Flexibility

Mechanical anchors have preset load capacity limits based on their size (length and diameter). However, chemical anchors offer: Virtually unlimited embedment depth, allowing longer rods for increased load-bearing capacity. Customizable strength, as selecting a higher-grade steel or larger-diameter rod increases resistance to both tension and shear forces. Traditional expansion anchors are restricted to their preset dimensions, limiting their load capacity, while chemical anchors provide greater flexibility for high-load applications.

No Expansion Stress = Ideal for Cracked or Weak Concrete

Chemical anchors do not exert expansion pressure on the surrounding concrete, making them ideal for: Cracked concrete or weaker materials that might fail under expansion stress. Close-to-edge installations, where expansion anchors could cause cracks. Expansion anchors rely on outward pressure to hold in place, which can damage the concrete, especially in edge or shallow installations.

- Products

360ml Certified polyester chemical anchor for construction projects

GU-100 360ml

The 360ml polyester chemical anchor is a medium-sized option that offers greater flexibility in the market. It requires a specific caulking gun for proper...

Details400ml Epoxy chemical anchor designed for use in tropical weather conditions

GU-500 400ml 3:1

This 400ml epoxy chemical anchor, in a 3:1 injectable cartridge, is designed for rebar connections and heavy-duty anchoring. It's especially suitable for construction...

Details650ml Epoxy anchoring adhesive for high-temperature installations

GU-500 650ml 1:1

This 650ml, 1:1 ratio, slow-cure epoxy-based injection mortar is ideal for anchoring projects in high-temperature environments. The two-component pure...

DetailsETA approved injection epoxy chemical anchor designed for dowel bar retrofitting

GU-500SD 400ml 3:1

GU-500SD pure epoxy chemical anchor has successfully received the European Technical Assessment report ETA-24/0928, confirming its high performance and reliability...

Details360ml High bond strength epoxy acrylate chemical anchor for vertical and horizontal fixing

GU-600 360ml

The 360ml epoxy acrylate chemical anchor is a top-selling option for general fixations and reinforcement projects. It is particularly popular in the chemical...

Details360ml Styrene-free injection vinylester chemical anchor for fixing in corrosive environments

GU-2000 360ml

360ml Vinylester Chemical Anchoring Mortar – Fast Curing Resin Cartridge SystemGU-2000 360ml Vinylester Chemical Anchoring Mortar is one of the most...

Details

What is chemical anchor? | Sold in 40 Countries Injectable Chemical Anchors Manufacturer Since 1997 | Good Use

Located in Taiwan since 1997, Good Use Hardware Co., Ltd. has been an injectable adhesive mortars and anchors manufacturer. Their main products, including injection cartridges, chemical mortars, chemical anchors, anchor capsules, polyester resins and vinylester resins, which are sold in 40 countries.

Reputable factory of chemical anchor in Taiwan produces the widest range of adhesive anchor solutions for your concrete anchoring applications. with more than 15 years manufacturing experience for Chemical Anchor System, Injection Cartridge System, Construction Chemical Mortar and more. Certified chemical anchor solutions with wide selections of adhesive materials including epoxy anchors, concrete anchors, resin anchors for heavy loads in rebar application, diamond drilled holes and anchoring in solid concrete. Non-drip formula, ideal for overhead installation. Chemical anchor bolt and anchor fixings included for efficient, hassle-free, labor-saving chemical anchoring.

Good Use has been offering customers certified and tested high-quality chemical anchors, both with advanced technology and 25 years of experience, Good Use ensures each customer's demands are met.