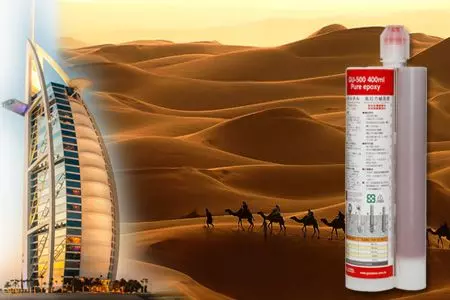

650ml Epoxy anchoring adhesive for high-temperature installations

GU-500 650ml 1:1

Slow Cure Epoxy Resin Chemical Mortar

This 650ml, 1:1 ratio, slow-cure epoxy-based injection mortar is ideal for anchoring projects in high-temperature environments. The two-component pure epoxy chemical anchor is styrene-free and low-odor, making it safe for use in enclosed or poorly ventilated areas. It's perfect for securing machinery, staircases, reinforcement bars (rebars), and threaded rods to concrete, stone, masonry, brick, rock, and other construction surfaces. The pure epoxy system offers a longer working time and improved flexibility during installation, ensuring strong, reliable bonds. Available in both 650ml and 600ml options.

Chemical Fixing System - Ultimate Performance Pure Epoxy Anchor

A high-performance epoxy mortar designed for heavy-duty anchoring. This advanced chemical anchor is ideal for applications requiring superior performance to ensure secure anchoring in critical conditions, temperature variations, or installation limitations. Tested in diverse anchoring scenarios at an ETAG-approved lab, we provide comparison reports to demonstrate its capabilities. Our epoxy injectable adhesive anchor is one of the strongest bonding fasteners available, meeting the growing demand for reliable anchoring solutions.

Specification of Pure epoxy chemical anchor

● Material: Pure Epoxy

● Model Number: GU-500

● Capacity: 650ml

● Mixing Ratio: 1:1

● Mixed Color: Gray

● Shelf Life: 18 months

● Standard Package: One cartridge with one mixer

● Other Accessory: Mixer, caulking gun, nylon sleeve, air pump, brush

Pure epoxy chemical anchor is ideal for deep embedment and large hole installation

● Heavy duty loading

● Great chemical resistance

● Ideal for deep embedment and diamond drilled holes

● Provide longer working time

● No shrinkage

● More efficient to use bigger cartridge capacity to save time for changing new cartridges

● Styrene free, low odor, and LEED tested for VOC (Volatile Organic Compounds)

● No health or safety concern to slow down your work

Pure Epoxy for Large Projects in Construction and Building

Pure epoxy is the preferred choice for large construction projects due to its exceptional strength and reliability. As concerns about secure anchoring and minimizing human error continue to grow, the demand for high-performance epoxy materials has increased. Epoxy anchoring is especially valued for its advanced capability in rod and rebar doweling within concrete, making it a high-consumption material in building projects. The larger volume options help save time by reducing the need to frequently replace cartridges, offering greater efficiency and cost-effectiveness for large-scale applications.

Strongest Injection Epoxy Anchoring Adhesive for All Fixing Solutions

Our non-drip formula epoxy anchoring adhesive is designed for optimal performance in overhead installations and suspension anchorage. This versatile, multi-purpose pure epoxy features a longer curing time, providing increased flexibility for a wide range of applications. Given the importance of climate suitability and temperature adaptability for chemical anchors, we have equipped our facilities to simulate various global anchoring temperatures. Extensive testing ensures the highest quality and performance. The steady characteristics of epoxy make it particularly effective in tropical zones, where durability and reliability are essential for long-term use.

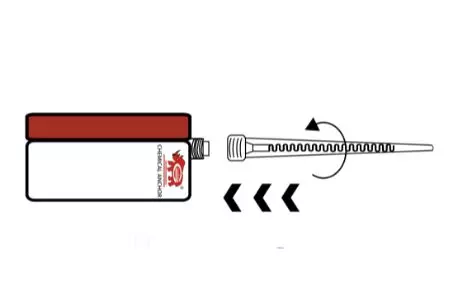

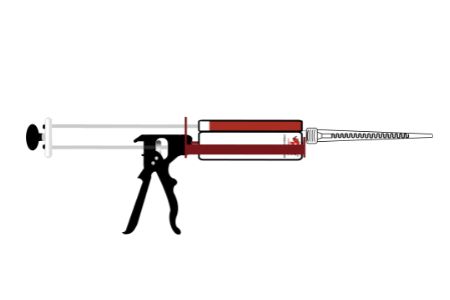

The Secret to Extruding 600/650ml Cartridges - Pull the Trigger with a Steady Rhythm

The 600ml/650ml side-by-side cartridge is quite large, with a capacity of 600ml for resin mortar. When dispensing the resin mortar, it’s important to do so slowly to allow the material to flow smoothly from the opening of the tube. Avoid pulling the trigger too quickly, as excessive speed can create pressure, causing the mortar to leak from the back plunger or potentially causing the caulking gun to jam. For optimal performance, pump the mortar at a steady, rhythmic pace. If using an electric cordless caulking gun, also pay attention to the speed at which the material is dispensed to ensure smooth and efficient application.

All Good Use Chemical Anchors - Qualified by IWB Lab in Germany and CSTB Lab in France

At present, there are no accredited laboratories in Asia for testing bonding anchors in compliance with European Technical Assessment (ETA) standards. Our chemical anchors undergo thorough testing according to EAD 330087-01-6001 and EAD 330499-00-0601 standards for rebar and threaded rod fasteners. We work closely with top experts in Europe who possess over 20 years of experience in the fastener sector. Our dedication to research and development drives continuous enhancements in our products and the advancement of our international certifications for chemical anchors.

Technical Data

SOLID SUBSTRATE REBAR INSTALLATION DETAILS

| Pressure | Destroy Haul Strength (Kgf/KN) |

Safety Haul Strength (Kgf/KN) |

Working Standard (mm) |

||||||

| Concrete Strength | 4,000 psi | 280 kg/cm2 | 4,000 psi | 280 kg/cm2 | Hole Diameter | Hole Depth | |||

| Rebar No. | #3 | (Φ10) | 3,607 | 36.4 | 1,202 | 12.1 | 13 | 90 | |

| #4 | (Φ12) | 6,409 | 64.7 | 2,136 | 21.6 | 16 | 125 | ||

| #5 | (Φ16) | 9,695 | 97.9 | 3,232 | 32.6 | 20 | 145 | ||

| #6 | (Φ20) | 13,655 | 137.9 | 4,552 | 46.0 | 25 | 170 | ||

| #7 | (Φ22) | 18,672 | 188.6 | 6,224 | 62.9 | 28 | 200 | ||

| #8 | (Φ25) | 24,032 | 242.7 | 8,011 | 80.9 | 32 | 225 | ||

| #9 | (Φ28) | 27,364 | 276.4 | 9,121 | 92.1 | 37 | 260 | ||

| #10 | (Φ32) | 31,730 | 320.5 | 10,577 | 106.8 | 40 | 290 | ||

| #11 | (Φ36) | 35,843 | 362.1 | 11,948 | 120.7 | 42 | 320 | ||

| Remarks: | 1. Concrete Strength fc': 280kg/cm2 (4,000 psi) 2. Rebar Strength: #3~#5 fy: 2,800 kgf/cm2, #6~#11 fy= 4,200 kgf/cm2 |

||||||||

CURING TIME TABLE

| Temperature (°C) | Gelling | Full Curing |

| 5~10 | 1-2 hr. | 90 - 100 hr. |

| 10~20 | 30-60 min. | 30 - 60 hr. |

| 20~30 | 14-30 min. | 14 - 22 hr. |

| 30~40 | 10-20 min. | 6 - 12 hr. |

| Please make pull off test for at least 24 hours after full cured. | ||

FIXING CONSUMPTION PER CARTRIDGE

| Anchor Size | Hole Diameter (mm) |

Hole Depth (mm) |

Number of Fixings |

| 650ml | |||

| M8 | 10 | 80 | 126 |

| M10 | 13 | 90 | 75 |

| M12 | 16 | 120 | 33 |

| M16 | 20 | 145 | 17 |

| M20 | 25 | 170 | 9 |

| M24 | 28 | 210 | 6 |

| M30 | 35 | 270 | 3 |

| M36 | 40 | 330 | 1 |

| Note: Based on continuous installation without interruptions or nozzle changes. Provided as a guide and will vary with temperature. | |||

- Related Products

-

400ml Epoxy chemical anchor designed for use in tropical weather conditions

GU-500 400ml 3:1

This 400ml epoxy chemical anchor, in a 3:1 injectable cartridge, is designed for rebar connections...

DetailsETA approved injection epoxy chemical anchor designed for dowel bar retrofitting

GU-500SD 400ml 3:1

GU-500SD pure epoxy chemical anchor has successfully received the European Technical Assessment...

DetailsETA approved high-strength epoxy chemical anchor for concrete mounting systems

GU-500SD 585ml 3:1

GU-500SD is our ETA-approved, high-performance pure epoxy anchoring solution, specifically...

Details600ml Two-component injection chemical adhesive applicator

#217

The #217 dual-component manual caulking gun is designed for 1:1 ratio 600ml and 650ml side-by-side...

Details650ml Heavy duty ergonomic epoxy sealant applicator gun

HC7-600

The HC7-600 is a professional heavy-duty dual-barrel caulking gun designed for 600ml and 650ml...

DetailsMixing nozzle for 1:1 and 3:1 chemical anchor

#818

Static mixer nozzles are applied to adhesive cartridges to mix and dispense two component adhesives....

Details - Files Download

-

GU-500 650ml 1:1 Pure Epoxy Chemical Anchor Catalogue

Good Use offers 650ml epoxy chemical anchors for large-diameter rebar and rod fixings, with strength data on dry concrete detailed in the catalog.

DownloadGU-500 650ml Pure Epoxy Chemical Anchor Technical Data Sheet

The GU-500 data sheet includes installation steps, curing time, edge distance tests, and reference volume per hole for rebar and threaded rods.

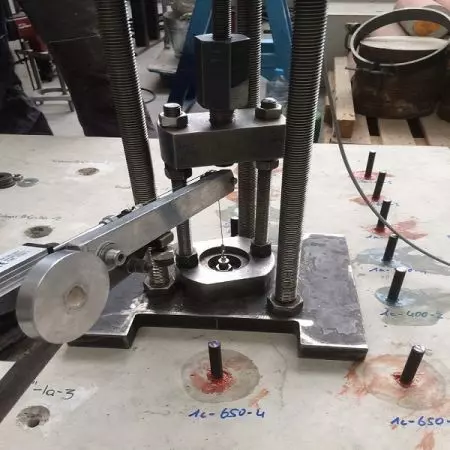

DownloadGU-500 SGS Tensile Strength Testing Report

GU-500 conducted pull-out test at SGS per ASTM E488-96 on 4000 psi concrete with various bolt sizes.

DownloadGU-500 AIT Tensile Strength Test Report-D25mm

GU-500 pure epoxy chemical anchors underwent a tensile test with rebar in 25mm diameter drilled holes at AIT, Thailand.

DownloadGU-500 AIT Tensile Strength Test Report-D16mm

GU-500 pure epoxy chemical anchors underwent a tensile test with rebar in 16mm diameter drilled holes at AIT, Thailand.

Download - Installation Guide

- Gallery

650ml Epoxy anchoring adhesive for high-temperature installations - Slow Cure Epoxy Resin Chemical Mortar | Sold in 40 Countries Injectable Chemical Anchors Manufacturer Since 1997 | Good Use

Located in Taiwan since 1997, Good Use Hardware Co., Ltd. has been an injectable adhesive mortars and anchors manufacturer. Their main products, including 650ml Epoxy anchoring adhesive for high-temperature installations, injection cartridges, chemical mortars, chemical anchors, anchor capsules, polyester resins and vinylester resins, which are sold in 40 countries.

Reputable factory of chemical anchor in Taiwan produces the widest range of adhesive anchor solutions for your concrete anchoring applications. with more than 15 years manufacturing experience for Chemical Anchor System, Injection Cartridge System, Construction Chemical Mortar and more. Certified chemical anchor solutions with wide selections of adhesive materials including epoxy anchors, concrete anchors, resin anchors for heavy loads in rebar application, diamond drilled holes and anchoring in solid concrete. Non-drip formula, ideal for overhead installation. Chemical anchor bolt and anchor fixings included for efficient, hassle-free, labor-saving chemical anchoring.

Good Use has been offering customers certified and tested high-quality chemical anchors, both with advanced technology and 25 years of experience, Good Use ensures each customer's demands are met.