Why Does Chemical Anchor Resin Fail to Mix Evenly?

On construction sites, it is sometimes encountered that chemical anchor resin does not mix evenly. This issue not only affects the curing process but may also reduce anchoring strength. There are many factors that can cause uneven mixing of the resin. We have summarized the most common causes and practical solutions to help you avoid problems during installation.

The reasons for uneven mixing of chemical anchor resin can be categorized into the following seven aspects:

Static Mixer Issues

If the spiral structure inside the static mixer is too short or poorly designed, the resin and hardener cannot be thoroughly blended; in addition, prolonged use may cause internal blockages or aged residue, further compromising the mixing quality.

Failure to Discard Initial Resin

The first portion of resin extruded is often not fully mixed. If this initial segment is not discarded according to standards and is used directly, it can cause an imbalance in the mixing ratio.

Incompatible Dispensing Tool

Using a dispenser/caulking gun with unbalanced thrust or poor design may result in different extrusion speeds for the two components, leading to uneven mixing ratios.

Cartridge Storage or Environmental Factors

Exposure to moisture or high temperatures can disrupt the flow balance between resin and hardener in chemical anchors, leading to uneven mixing. Expired or long-stored resin may separate or settle, making uniform blending difficult. Extreme cold increases viscosity, while excessive heat causes inconsistent flow—both harming mixing quality.

Poor Cartridge Design

If the outlet diameters of the dual-component cartridge are inconsistent, or if the partition is not properly sealed, the resin-to-hardener ratio will be imbalanced, resulting in poor mixing.

Incorrect Raw Material Ratio or Manufacturing Issues

During production, inaccurate formulation ratios or insufficient filling precision may also lead to poor mixing performance, even when using a static mixer.

Installation Errors

If the applicator is operated too quickly, the resin may not remain in the static mixer long enough for thorough blending; furthermore, if the mixer is not installed correctly or is reattached without proper positioning after removal, leakage or loosening may occur, resulting in poor mixing performance.

After understanding the main factors that cause uneven mixing of chemical anchor resin, to ensure smooth installation and uniform mixing, we recommend the following practices along with using high-quality chemical anchor products for optimal performance:

- Use certified static mixers and the manufacturer-recommended dispensing guns, and regularly inspect your tools and accessories.

- Purge approximately 10–20 cm of initial resin before starting the actual installation.

- Ensure the resin is within its shelf life and apply it under the recommended temperature range.

- Use certified chemical anchor products that have passed quality inspections to avoid incorrect mixing ratios caused by design or manufacturing defects.

- Maintain a steady and appropriate extrusion speed when operating the dispensing gun.

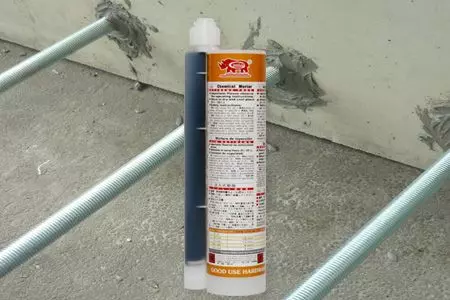

The quality of chemical anchor resin installation depends on product design, formulation accuracy, and attention to detail during on-site operations. By following correct installation procedures and using certified, high-quality products, uneven mixing issues can be effectively prevented, ensuring structural safety and reliable anchoring strength. Good Use chemical anchor strictly controls production and quality, providing stable and reliable solutions, making it your trusted choice for safe and efficient installation.

- Products

ETA approved high-strength epoxy chemical anchor for concrete mounting systems

GU-500SD 585ml 3:1

GU-500SD is our ETA-approved and CE marked high-performance pure epoxy anchoring solution, specifically engineered for demanding structural applications....

Details360ml Certified polyester chemical anchor for construction projects

GU-100 360ml

The 360ml polyester chemical anchor is a medium-sized option that offers greater flexibility in the market. It requires a specific caulking gun for proper...

Details360ml Styrene-free injection vinylester chemical anchor for fixing in corrosive environments

GU-2000 360ml

360ml Vinylester Chemical Anchoring Mortar – Fast Curing Resin Cartridge SystemGU-2000 360ml Vinylester Chemical Anchoring Mortar is one of the most...

Details

Why Does Chemical Anchor Resin Fail to Mix Evenly? | Sold in 40 Countries Injectable Chemical Anchors Manufacturer Since 1997 | Good Use

Located in Taiwan since 1997, Good Use Hardware Co., Ltd. has been an injectable adhesive mortars and anchors manufacturer. Their main products, including injection cartridges, chemical mortars, chemical anchors, anchor capsules, polyester resins and vinylester resins, which are sold in 40 countries.

Reputable factory of chemical anchor in Taiwan produces the widest range of adhesive anchor solutions for your concrete anchoring applications. with more than 15 years manufacturing experience for Chemical Anchor System, Injection Cartridge System, Construction Chemical Mortar and more. Certified chemical anchor solutions with wide selections of adhesive materials including epoxy anchors, concrete anchors, resin anchors for heavy loads in rebar application, diamond drilled holes and anchoring in solid concrete. Non-drip formula, ideal for overhead installation. Chemical anchor bolt and anchor fixings included for efficient, hassle-free, labor-saving chemical anchoring.

Good Use has been offering customers certified and tested high-quality chemical anchors, both with advanced technology and 25 years of experience, Good Use ensures each customer's demands are met.