Chemical Anchor Failure Modes You Should Know Before Installation

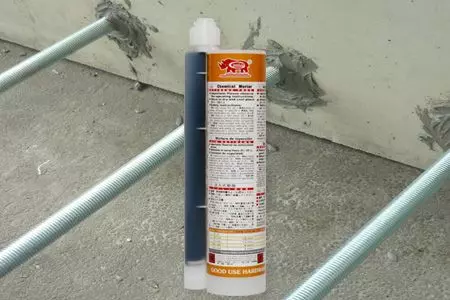

Chemical anchors provide strong bonding strength to connect objects into concrete and masonry. They are commonly used for all kinds of fixing projects from house repair to civil construction applications. To achieve a successful chemical anchoring and to ensure the reinforcement is strong enough, there are a few key factors to comply and not a single one can be omitted. For example, the diameter of the rod or rebar, the type of chemical anchor, the depth of the hole(embedment), the condition of the concrete (compressive strength), and the installation method. These key factors are influencing the strength of anchorage system and are critical in calculating the load capacity of chemical anchor.

Best Practices for Chemical Anchor Installation and Pull-Out Testing

An installation test and pull off test before formal installation is recommended. Even though most of manufacturers provide testing report to support their chemical anchors. However, the conditions of the applications would not be exactly the same as the one they conducted in the test report. Thus, we always encourage customers to run a test and see if the result meets the requirement. If the result of pull off test is like any one of the 5 modes below, it means the anchoring failed. We should go back and check if there is any omission or incorrect action during the calculation and installation, then arrange a test again.

A. Concrete Cone Failure

The steel anchor pulls out of the hole with a cone of concrete stuck to it. It usually happens with shallow embedment depth. If the embedment is not too deep, the top of concrete is quite weak and this type of failure will likely occur.

B. Failure At The Mortar/Concrete Boundary Line

The steel anchor pulls out together with its adhesive casing. This failure is the separation at the boundary between the adhesive and concrete. It might cause by smooth wall of the hole. Roughening the wall of the hole by brushing it with a steel wire brush and then blowing out the dust will roughen the hole and improve the loads. If the dust is not cleaning well, it would like a layer of powder between the adhesive and concrete.

C. Failure At The Mortar/Steel Boundary Line

The steel anchor is pulled out of the adhesive casing. In the other word, the adhesive casing remains in the hole. It could be something wrong with the chemical anchor or the steel anchor is oily or has too much loose rust on the surface.

D. Mixed Failure Mode

The steel anchor is pulled out with the bottom part of the adhesive casing remaining in the hole. A combination of (b) and (c). This the worst failure mode.

E. Steel Anchor Failure

The steel anchor is snapped under tension load. It usually occurs for long embedment lengths. With this result, we get the idea that the bond strength of chemical anchor is very good.

Nowadays more and more install crews use epoxy solutions for the projects as epoxy anchoring is cheaper, easier and faster to install. But, if the epoxy anchors are not installed and cured properly, the epoxy will no longer maintain the required loading strength to ensure structural integrity of the anchor. The anchoring failure may result in collapse or partial collapse of the structure, endanger human life and/or cause considerable economic loss. It is very important for contractors, install crews and engineers to cooperate and design the best solution that meet industry requirement and install the chemical anchors correctly.

Good Use Hardware is the top manufacturer in Taiwan, specializing in high-quality chemical anchor adhesives and offering professional research and development expertise. Our knowledgeable sales team is available to assist you in selecting the right chemical anchor for your anchoring needs.

- Products

360ml Certified polyester chemical anchor for construction projects

GU-100 360ml

The 360ml polyester chemical anchor is a medium-sized option that offers greater flexibility in the market. It requires a specific caulking gun for proper...

Details400ml Epoxy chemical anchor designed for use in tropical weather conditions

GU-500 400ml 3:1

This 400ml epoxy chemical anchor, in a 3:1 injectable cartridge, is designed for rebar connections and heavy-duty anchoring. It's especially suitable for construction...

Details650ml Epoxy anchoring adhesive for high-temperature installations

GU-500 650ml 1:1

This 650ml, 1:1 ratio, slow-cure epoxy-based injection mortar is ideal for anchoring projects in high-temperature environments. The two-component pure...

DetailsETA approved injection epoxy chemical anchor designed for dowel bar retrofitting

GU-500SD 400ml 3:1

GU-500SD pure epoxy chemical anchor has successfully received the European Technical Assessment report ETA-24/0928, confirming its high performance and reliability...

Details360ml High bond strength epoxy acrylate chemical anchor for vertical and horizontal fixing

GU-600 360ml

The 360ml epoxy acrylate chemical anchor is a top-selling option for general fixations and reinforcement projects. It is particularly popular in the chemical...

Details360ml Styrene-free injection vinylester chemical anchor for fixing in corrosive environments

GU-2000 360ml

360ml Vinylester Chemical Anchoring Mortar – Fast Curing Resin Cartridge System GU-2000 360ml Vinylester Chemical Anchoring Mortar is one of the most...

Details

Chemical Anchor Failure Modes You Should Know Before Installation | Sold in 40 Countries Injectable Chemical Anchors Manufacturer Since 1997 | Good Use

Located in Taiwan since 1997, Good Use Hardware Co., Ltd. has been an injectable adhesive mortars and anchors manufacturer. Their main products, including injection cartridges, chemical mortars, chemical anchors, anchor capsules, polyester resins and vinylester resins, which are sold in 40 countries.

Reputable factory of chemical anchor in Taiwan produces the widest range of adhesive anchor solutions for your concrete anchoring applications. with more than 15 years manufacturing experience for Chemical Anchor System, Injection Cartridge System, Construction Chemical Mortar and more. Certified chemical anchor solutions with wide selections of adhesive materials including epoxy anchors, concrete anchors, resin anchors for heavy loads in rebar application, diamond drilled holes and anchoring in solid concrete. Non-drip formula, ideal for overhead installation. Chemical anchor bolt and anchor fixings included for efficient, hassle-free, labor-saving chemical anchoring.

Good Use has been offering customers certified and tested high-quality chemical anchors, both with advanced technology and 25 years of experience, Good Use ensures each customer's demands are met.